The tube to tube sheet welding process is a key part of fabrication in critical components.

This overview details which industries the process is commonly used and it’s applications, as well as key equipment needed.

Where is it used?

- Food and Beverage / Pharmaceutical / Chemical/Sanitary Industry

- Hygienic requirements and resistance to corrosive media under pressure and temperature

The final product must not be affected by contamination or microbial growth.

Benefits.

- Reproducible, pure welds for optimum resistance against microbiological influenced corrosion

- Smooth welds for easy cleaning to meet the hygienic requirements

- Controlled and constant penetration

- Minimized heat input in the heat affected zone

- Minimized oxidation

- Metallurgical superiority

- ISO documented weld quality

- Gain of time thanks to reduced testings (non-destructive/destructive testing)

- Automatic documentation of the welds within integrated quality management systems

- Tube O.D. 6,0 – 220 mm

- Wall thickness 0,8 – 3 mm

- Material 304 and 316 L type stainless steel

Applications.

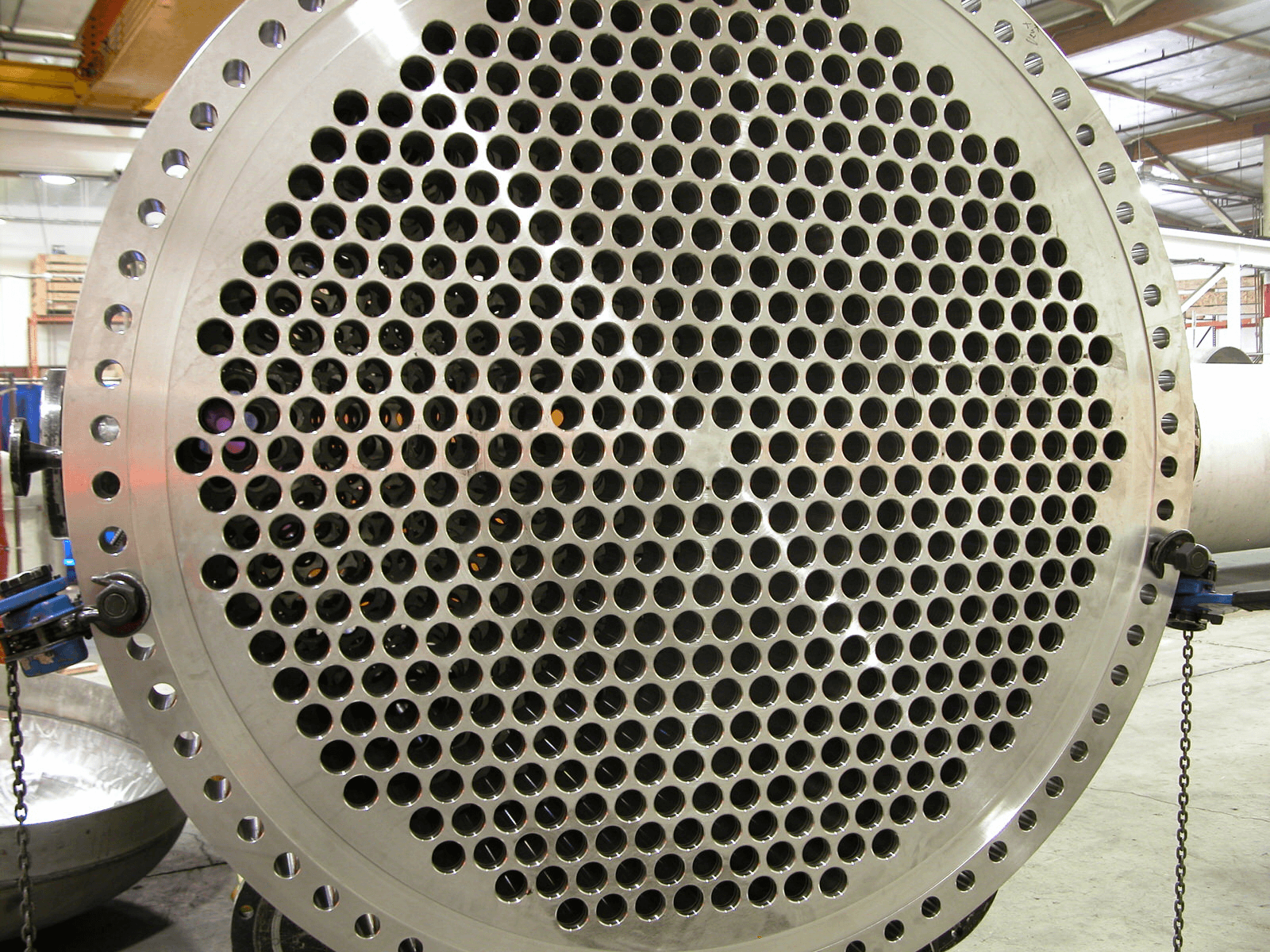

Thermal transfer equipment and heat exchangers.

Heat exchangers are widely used in many ways and are seen in many types of industrial, commercial and residential applications. Heat exchangers come in many configurations, sizes and materials of construction. Some of the various types of heat exchangers are shell and tube, plate coil, pipe coil, bayonet and air finned tube.

High productivity with zero default rates

For sterilisation in food processing, heat exchanger fabrication for power generation, air cooler production.

Materials: Carbon – stainless steels and related alloys, Titanium, Zirconium, Duplex.

Equipment.

Pre-used Polysoude orbital welding power sources and weld heads for sale from Westermans

For more details follow link to used Polysoude orbital weld head or Polysoude P6 power supply

Unique features

- Compatible for work with all series of Polysoude power sources: xx4 series without AVC; xx6 and PC series with AVC.

- Various toolings are available to accommodate with all existing tube joint designs.

- Interchangeable I.D. related, flexible centring mandrels to comply with standard tube tolerances.

- Particularly designed for high duty cycle applications by means of high temperature resistant materials and closed loop water cooling.

- Endless rotating torch, no cable wrap-up by means of a unique collector to supply the torch with welding current, shielding gas and cooling liquid.

- Closed loop regulation to ensure precise, constant or pulsed welding speed.

- Encoder for position based control of the welding program.

- Return-to-home feature: the electrode gear automatically returns to its starting position.

Accessories and options for particular needs

- Flexible centring mandrel for all tube I.D.’s.

- Filler wire feeder modules on board (1,5 kg / 4″ spool) or floor mounted POLYFIL (15 kg spool) with adjustable wire guide and liner (wire size 0,8 mm).

- Pneumatic prepositioning device to increase handling comfort and therefore quality and productivity.

- Various standard torch angles and special toolings are available for all existing tube joint designs and types of heat exchangers.

- Purge gas chamber for titanium and inconel, independent from torch shielding gas, reducing purge time and weld oxidation.

- Extension cable (15 m).

- Dual weld head switch box.

- Compact shipping case for transport and storage.

- Tungsten electrodes, pre-sharpened.

This product can be used for

Tube Sheet, Tube-Header collector, Internal Bore welding

To see the whole range of used and refurbished Orbital welding equipment for Sale please view our Stock at Orbital Systems

Got something to sell? We buy Welding and Cutting equipment from around the world.

600+ machines in stock

600+ machines in stock Worldwide delivery

Worldwide delivery Rated Excellent

Rated Excellent Warranty included

Warranty included Qualified engineers

Qualified engineers

comments

Pingback: Equipment for Orbital Welding of Tube/Pipe | Westermans Blog