Why hygienic welding is so critical in the food and beverage industry.

The hygienic requirements of the food and beverage industry place high demands on the welds that hold tanks, pipes and vessels together.

The requirements for a high-quality weld and weld surface finish are paramount in dairy and other food and beverage industries. Consequences of poor surface and weld quality can be costly and dangerous.

Recent contamination scares in the dairy sector provide some examples of the consequence of not getting things right.

In effect, every metre of weld inside a storage or process tank or vessel represents a risk to be managed. Fabricators must make significant efforts to ensure that both the weld integrity is adequate, and that the surface finish meets the specified requirement for hygiene.

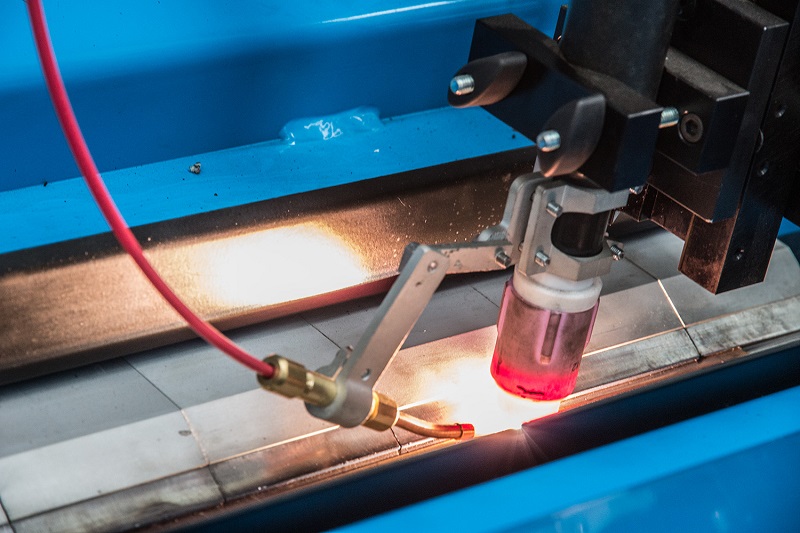

Automatic plasma arc welding (PAW).

Automated welding equipment produces higher quality welds with improved efficiency.

The PAW process enables an excellent weld quality to be produced, with the introduction of minimal heat. Plus, no removal of parent material required for weld preparation.

Unlike the TIG process, which is susceptible to tungsten inclusions from the exposed electrode, PAW has no exposed electrode. Consequently, this significantly reduces the risk of inclusions.

Weld quality is evident by the superior radiography test performance that results from the PAW method. Butt welds up to 8 mm thickness can be completed in a single pass, with only a gas backing shield required.

Weld reinforcement is minimised, assisting in the subsequent surface treatment to obtain a smooth weld finish suitable for sanitary applications.

Automated Seam Welding.

Seam welds of tanks produced consistently by the Plasma Arc Welding process, deliver the highest quality in sanitary finishing. Essential for clients in the food, beverage and pharmaceutical industries.

Automated systems not only reduce fabrication time and costs, but result in a consistently smooth and high-quality finish to weld seams. Integral to achieving a sanitary finish.

The surface roughness of the internal weld seams is specified in ‘Ra’ — a measurable roughness, in micrometres, which is obtained using an Ra meter.

Traditionally, surface roughness has been specified in ‘grit’, which is not practical in a sanitary application. Grit refers to how course the polishing medium is. The finished surface is not measurable in grit, and may have a varied roughness when completed by different operators.

This is not ideal when working within hygienic environments.

Westermans International can supply both new and refurbished, automated plasma welding systems for longitudinal welding.

Manufacturers of automatic plasma arc welding equipment include ProArc, Jetline, WeldLogic, Thermal Arc and Bode.

Not sure if this is the process for you?

5 benefits include:

- High Quality Welds

- Consistent Productivity

- Reduced labour Costs

- Low Cost Welding Equipment

- 24/7 Support

We are happy to weld samples of your materials. Please contact our Technical Sales Team to discuss your projects, processes and requirements.

Not biased to any one brand, we have a selection of seam welding systems to suit every budget with some equipment supplied within 7-14 days.

To view all of our seam welding equipment for sale click here

600+ machines in stock

600+ machines in stock Worldwide delivery

Worldwide delivery Rated Excellent

Rated Excellent Warranty included

Warranty included Qualified engineers

Qualified engineers

comments

Thank you this is beautiful and good information i like it thanks man.

The hygiene is the important factor for which the care should be taken as it can affect ones health. Westermans you people are doing good job. Also I have heard from my neighbour about your services. I would definitely purchase from you’ll next time.

Thank you Jasmine for taking time to read and comment on our post. I see you are involved in many industries. Please view the speciality equipment we have for sale include hot wire cladding systems made by Fronius.