Reduce Micro Bacteria with Orbital Welded Piping.

It’s owing to the improper welds of pipes and tubes servicing the food and beverage industry, that result in them being more susceptible to the growth of micro bacteria and organisms.

The high-quality, end results of orbital cutting, bevelling and welding machines reduces the microbial growth of bacteria. Smooth pipes reduce the growth of bacteria and diseases in pipes.

However, when two parts of a pipe or tube are joined, a rough surface with edges can be created. This can promote microbial growth.

Equipment Usage.

Orbital tube and pipe equipment; cutters, bevellers and welders are capable of creating a nearly perfect connection. Using new or used orbital welding equipment to construct plants, piping systems, reduces microbial growth. specialised process that the welders use for the associated pipe building.

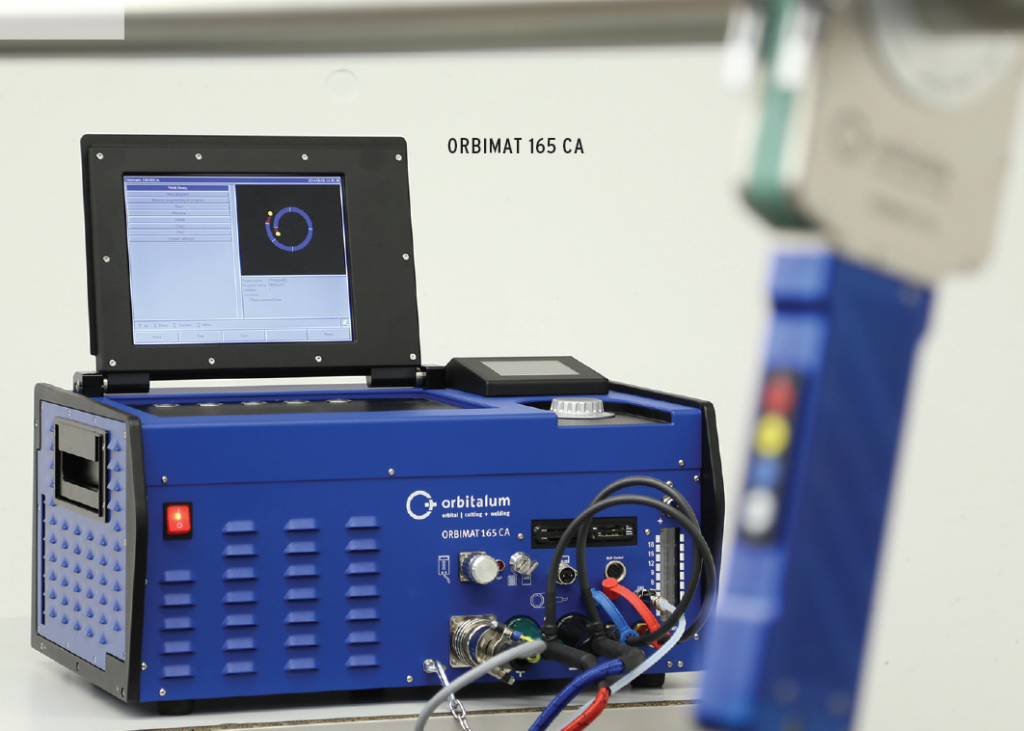

Power supply units can be fitted and perform with closed as well as open welding-head solutions.

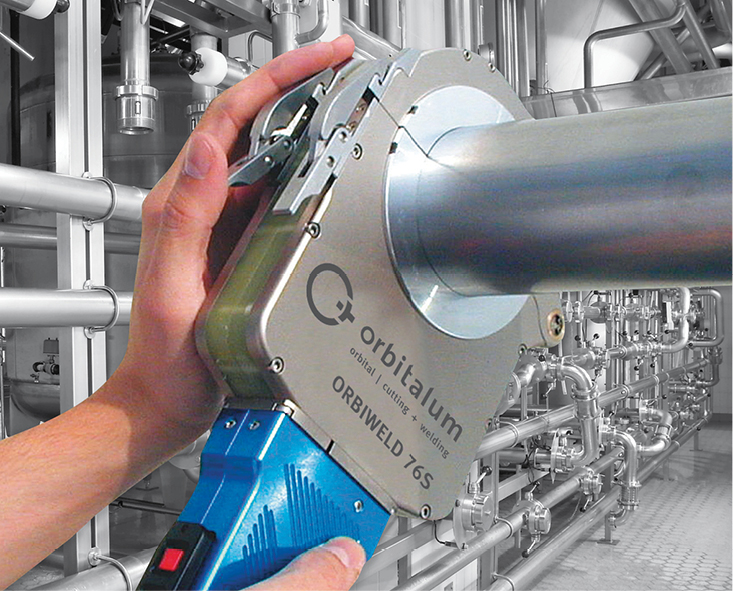

Enclosed Head Orbital Welding.

On the closed-welding head, the welding point is in an enclosed housing. This prevents excessive sparks or arcs from causing damage.

Closed-head welders are used in environments that are difficult to control. While an open-head system is used in a clean environment, like fabrication work. Therefore wind, water and other environmental factors cannot affect the welding process.

Orbital Welding Equipment Manufacturers.

There are a number of leading manufacturers of pipe and tube cut, bevel and weld equipment. Orbitalum Orbimatic orbital welding equipment is now one of the leading European brands.

Offering an economical solution, Westermans International have been supplying a pre-used range of Orbitalum equipment for many years.

The Orbitalum range can be used to cut, bevel and weld a range of pipes. From 0.5” to 20”, with the pipe-wall thickness limited to a maximum of 9 mm in diameter.

Closed-welding head systems operate on fusion welding, limited to a maximum of 4” outer diameter and 3 mm pipe-wall thickness.

Orbitalum History.

The Orbitalum company started in 1960 has over the years acquired E.H. Wachs, Orbimatic, Georg Fischer. Please contact us should you need impartial advice on any used orbital pipe weld or prep equipment. Orbitalum will be at the Schweissen & Schneiden 2017 Exhibition in September. Visit the stand for current product information and demonstrations.

600+ machines in stock

600+ machines in stock Worldwide delivery

Worldwide delivery Rated Excellent

Rated Excellent Warranty included

Warranty included Qualified engineers

Qualified engineers

follow us on