The weld overlay cladding process provides protection for vulnerable fittings.

These include products such as pipes, valves, flanges and specialist fabrications used in any hostile environment.

Weld overlay is needed in a number of industry sectors where service conditions require corrosion resistant properties.

Weld overlay provides the assurance of a heavy-duty metallurgically-bonded protective layer that will not be undermined or dislodged in service.

The highly versatile weld overlay process provides the practical combination of readily available base materials, coated with a suitable corrosion-resistant alloy to protect any given area.

This provides the benefit of cost savings, as well as a reduction in lead time.

A wide range of applications can benefit from anti-corrosion weld overlay. These include pipelines, flanges, valves, vessels and specialist subsea equipment.

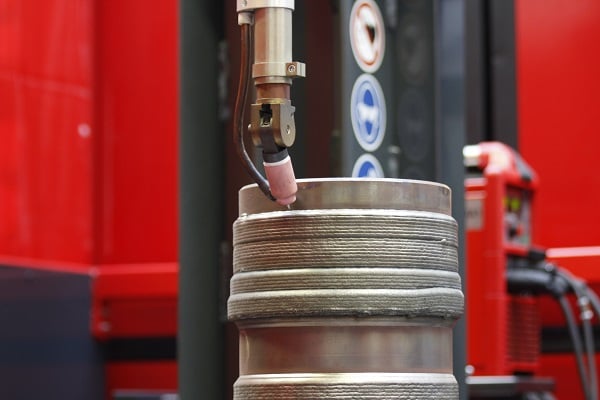

An array of component shapes and sizes can be clad at a specialised fabrication company, with a huge range of base material/cladding alloy alternatives.

Typical welding alloy materials include Inconel 625, Inconel 825, monel, hastalloy and stainless steels amongst many others.

TWI – Cladding is defined by the Welding Institute as; providing a corrosion or oxidation resistant surface on a less corrosion-resistant material.

An example of this is the deposition of a stainless steel or nickel-based layer on a carbon steel base.

One advantage of this technique is cost saving arising when surfacing a relatively inexpensive metal, such as a carbon steel. The process adds a more expensive but corrosion-resistant layer of stainless steel.

Material and weight savings may be gained when a clad, high strength, quenched and tempered steel is used in a corrosive environment.

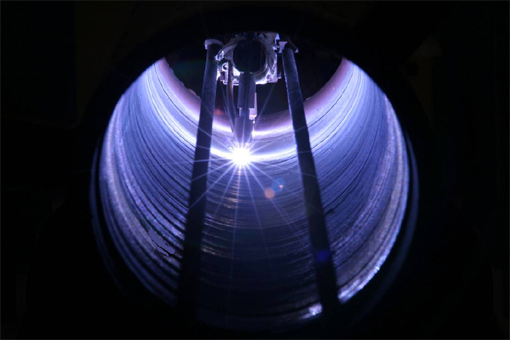

Conventional weld cladding is carried out primarily in circular bores with simple surfaces.

The component mounted on a turntable with the bore being welded centred on the turntable rotational axis.

During the cladding operation, the turntable rotates and the welding torch is stationary (moving up once a revolution).

A conventional column & boom (rack & pinion type) supports precision cross slides attached to the end of the boom.

The slides perform the task of moving the torch in two or more axes.

A typical installation consists of:

- A rack & pinion drive type column & boom for approximate positioning of the welding torch.

- A cross slide assembly for precise control of the torch.

- System control unit.

- Arc Control Unit for arc initiation, voltage and current detection.

- Welding Power Source: usually around 350Amp, 100% duty cycle

- Hotwire Power Supply, such as the PEC HWT-75 (75Amp, 100% duty cycle).

- Water cooler for cooling the welding torch.

- Welding torches (for example Fronius HVATT, HST, SBT) in lengths from 750 – 1750mm.

- Turntables and welding positioners, typically up to 10,000kg capacity.

- Operator pendant controls.

What is the difference between a Rotary Head welding system and a conventional one?

For as long as arc welding has been around, the welder would either manually move his welding torch around the joint or surface he is welding, or mount it on a turntable for mechanised rotation of the part.

Oil & Gas industry wellhead valves have become heavier (50 tons) and have more complex shaped bores that require the component to be mounted ‘off centre’ to the table rotating axis.

This results in accelerated wear of the supporting bearings and drive gears of the turntable.

Centring a bore on a large block valve to the table centre is also time-consuming and a strenuous task for the operator.

Faced with these on-going issues with conventional cladding technology, a major breakthrough was made in weld cladding technology by replacing the turntable altogether and rotating the torch instead of the component (which remains stationary). The torch is mounted on a weld head that rotates which gives rise to the name ‘Rotary Head’.

There is a great deal of new interest in hot wire welding and cladding. Although invented many years ago, this technology never really saw the light of day until recently.

One version or other is already being used by participants in the oil and gas industry, by the Navy, and by builders of aircraft engines.

Hot wire welding and cladding was the subject of a one-day conference at the FabTech Int’l and AWS Welding Show in Chicago.

Presentations were made on both hot wire GTAW and hot wire plasma processes.

The popular use of hot wire gas tungsten arc cladding of tube and piping for the offshore oil and gas industries. In another presentation, hot wire GTA “narrow groove” welding will be shown to have performed well on titanium.

Advantages are increased deposition rates and faster travel speeds.

The hot wire gas tungsten arc welding process has found increasing use over a wide range of groove welding, build-up and cladding operations. Commercially available and specialised hot wire equipment continues to promote application of the process for producing high-quality welds. Industries including nuclear, power generation, pressure vessel and offshore oil are the most common for use of the process.

Applications were presented to show the process capabilities, characteristics, benefits and limitations of the process.

Examples of process control and variations to consider were discussed based on welding requirements, materials, process variables, weld design and inspection.

Where a considerable amount of work is directed toward pressure vessel fabrication, hot wire gas tungsten arc welding is used extensively for the narrow gap welding of nickel-based alloys.

The hot wire process is also used for build-ups, butterings, and cladding of high-strength low alloy steel.

600+ machines in stock

600+ machines in stock Worldwide delivery

Worldwide delivery Rated Excellent

Rated Excellent Warranty included

Warranty included Qualified engineers

Qualified engineers

comments

Good article, thanks for sharing. However, is there any difference between overlay weld and surfacing?

Hi, I think it’s just a different term for an overlay weld. Depends where in the World you are too!

Thanks for writing on the cladding process, I’m not familiar with this word because I’m a learner, and learning welding as of now. But I will like to tell here that I found this term first time.

great