If you’re completing multi pass welds using MIG or flux cored welding processes, then this Magnatech Pipeliner II 609 could be the solution to repeatable, superior quality welds.

When producing multi-pass welds on pipes, it can be a costly and time consuming job for the amount of man hours required to complete the task manually.

Naturally, there has to be some allowance for human error to be accounted for too. After all people are not robots! Plus these errors can take extra material to rectify, a waste of precious time and money.

Repeatability can often be an issue with manual welding, welds need to be of exceptional quality when dealing with hazardous substances.

To achieve the results required, an automated system is now the industry preferred method. Offering faster welding speeds and consistent quality, these carriage-like machines are ultra portable and lightweight, making them the perfect in shop or field solution.

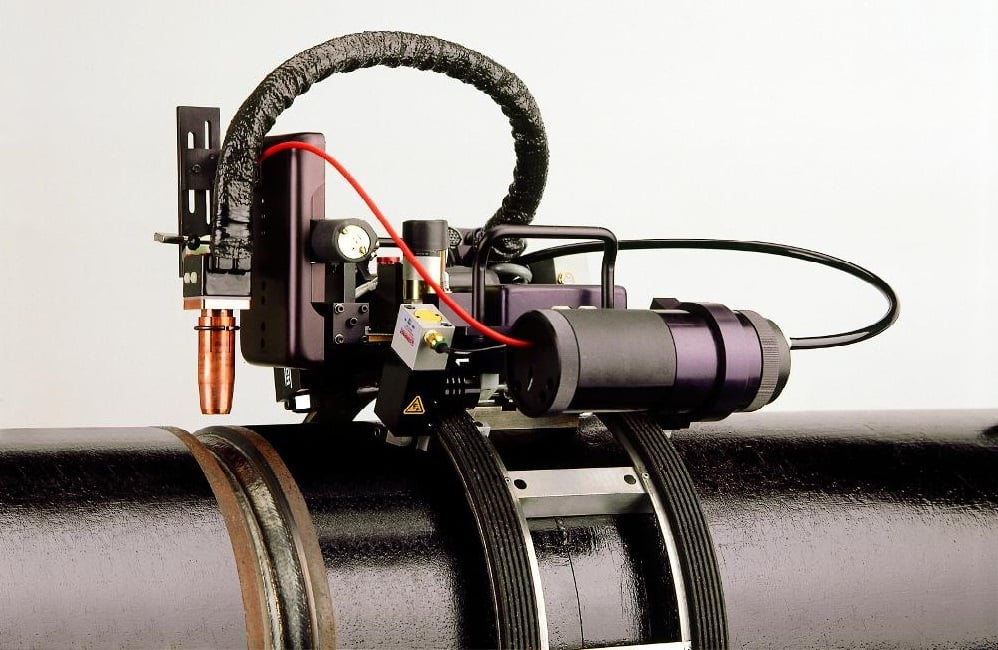

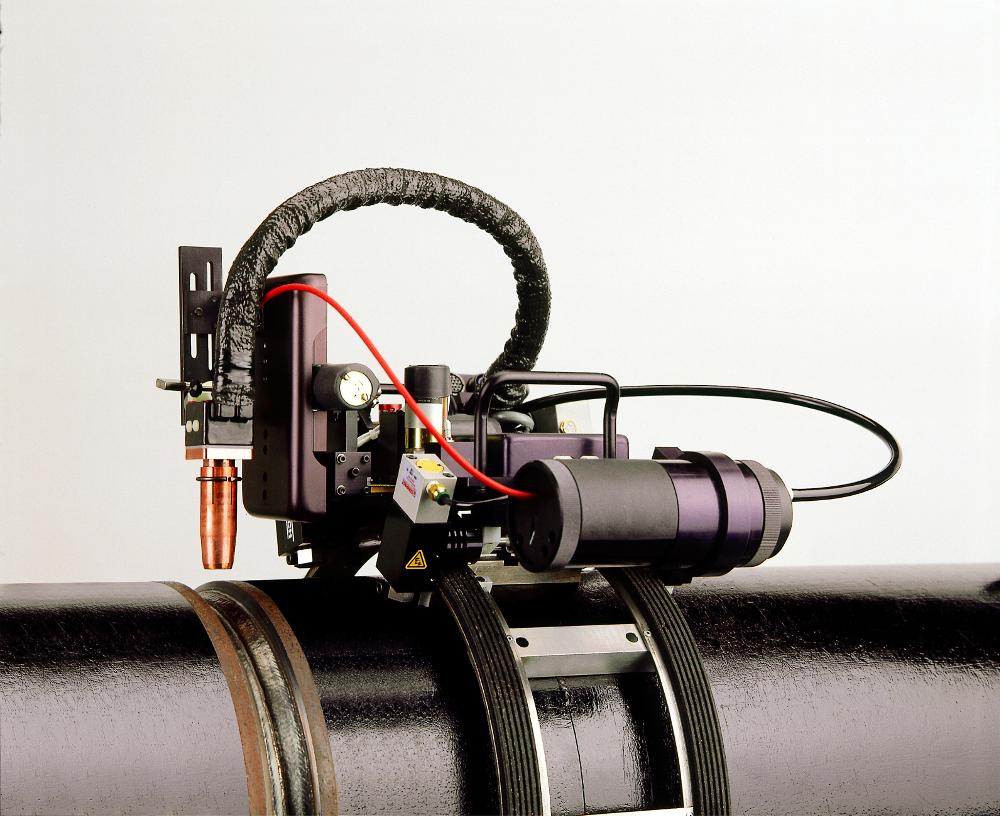

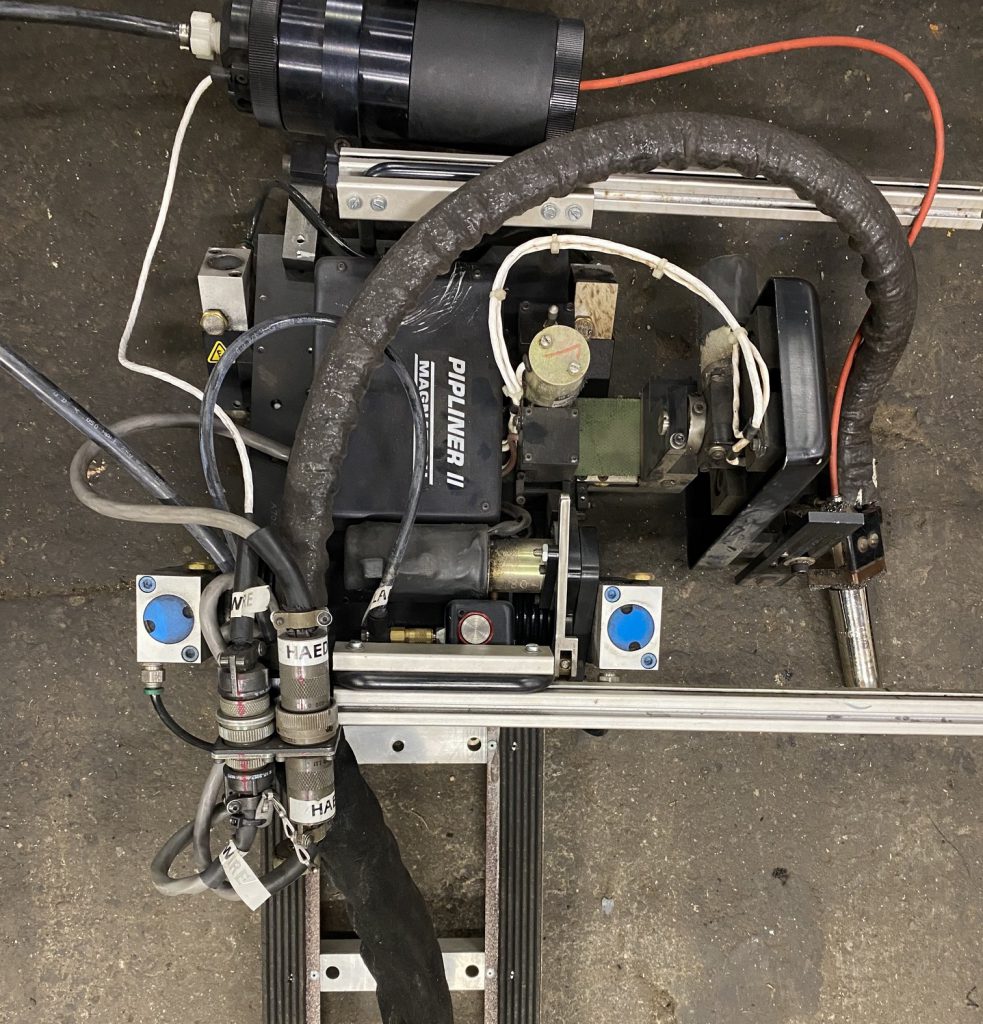

The Pipeliner II 609 from Magnatech is a complete system from one of the World’s leading brands. Fitted with Fronius MIG welding equipment, it could well be the new work horse of your equipment fleet.

System features:

- Magnatech Pipeliner II 609 carriage

- Fronius MPS 4000 GMAW/FCAW pipe welding power source

- 14″, 25″ and 36″ rings

- 90″ straight/flat track

- Full function capability – torch rotation, filler wire feed, push pull wire feed head, motorised arc gap control, electronic oscillation

- Workpiece size range from 169 – 1524mm (6″-60″) and larger

Designed for pipe to pipe and pipe to fitting welds in applications including gas, oil and water pipelines, steam piping, chemical, large diameter vessels, pilings etc.

The Pipeliner II improves productivity by increasing duty cycle, reducing repair rates and producing consistent quality welds even in extreme environments.

Have the confidence your machine will work on delivery. We offer warranty packages on all of our equipment as standard, this is usually 4 months and on a return to base policy. Overseas clients can be on a parts only basis if preferred/not possible to return the machine.

Export and domestic sales are handled professionally and efficiently, with all necessary documentation arranged as required.

See what our other clients are saying about us, take a look at our latest feedback and testimonials.

600+ machines in stock

600+ machines in stock Worldwide delivery

Worldwide delivery Rated Excellent

Rated Excellent Warranty included

Warranty included Qualified engineers

Qualified engineers

follow us on