Which is which and when do I use them?

A helpful yet simple explanation to the 3 main arc welding processes to help you decide what you need before you buy any welding equipment.

Stick Welding

Other name: Shielded Metal Arc Welding

Abbreviations: SMAW, FCAW, MMA

Overview.

A manual welding process, the stick welding process uses an electric current to form an electric arc, between the flux covered stick rod and the metals to be joined.

This is done by means of a power source, via either alternating current or direct current.

The coating of flux on the electrode then disintegrates, with the vapours given off acting as a shielding gas and a slag is formed to act as protection for the weld joint.

This process is often used in the maintenance and repair industry, construction of steel structures and in industrial fabrication to weld iron and steel mainly.

However the SMAW process is often a good choice for materials like aluminium, nickel and copper. FCAW (flux cord arc welding) was developed as an alternative to stick welding, the semi-automatic arc weld is often used in construction projects due to high-speed welding and portability.

Advantages.

Although the original welding process was founded in 1881, stick welding still has it’s advantages today. It is a versatile and simple process, leading to it’s popularity in the maintenance and repair sector. Equipment and consumable costs are also low and widely available, which makes it a popular choice for small businesses and amateurs alike.

Disadvantages.

However disadvantages include quality problems such as weld spatter, porosity issues, poor fusion, shallow penetration and cracking – hence this basic process does not have a place in a lot of welding applications requiring the high standards of today. Like all welding processes, standard health and safety practise such as PPE and fume extraction are required for operation.

MIG Welding

Other name: Gas Metal Arc Welding

Abbreviations: MIG or MAG or GMAW

Read below or skip straight to the video!

Overview.

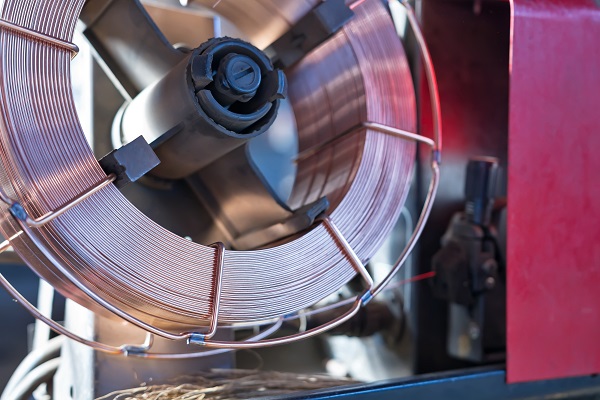

The process uses a shielding gas along the wire electrode, which heats up the two metals to be joined. The shielding gas protects the weld from atmospheric contamination, as the electric arc heats the wire to form the weld pool joining the material. This method most popularly uses a constant voltage and direct-current power source, however constant current and alternating current can be used and are beneficial for certain applications.

It has four primary methods of metal transfer: globular, short-circuiting, spray and pulsed-spray, each having their own properties and advantages/limitations.

- Globular: is considered the least desirable, due to it’s high heat transfer, poor weld surface and production of large amounts of spatter. However advantages include it’s use of CO2 as the shielding gas, which is the cheapest and most economical. Globular also offers high deposition rates, so could be considered when speed is required over weld aesthetics. Only possible for use with ferrous metals.

- Short-circuiting: uses a lower current than globular welding, offering a significantly reduced heat input. This enables the welding of thinner material and decreasing the amount of residual stress and distortion on the weld zone.

Leading to better quality welds and less spatter, with welding in all positions also possible.

However, this is done at a much slower rate, it is also critical to input parameters correctly to ensure a stable arc.

Short-circuit is not recommended for thicker materials as it can result in a lack of fusion and penetration due to lower arc energy. As with globular this process can only be used with ferrous metals. - Spray arc: Well suited for use with stainless steel and aluminium, spray arc metal transfer was the first metal transfer method using the GMAW process.

A high quality weld finish and elimination of spatter is achieved by the weld electrode metal being rapidly passed along the stable electric arc, from the electrode to the workpiece.

Due to the large weld pool produced by the high current and voltage required to complete the process, it is mostly suitable for thicker material above 6.4mm and also limits usage to flat and horizontal welding positions mainly.

Generally this process is not practical for root pass welds. Smaller electrodes and lower heat inputs can increase the versatility of the process. - Pulsed spray: Based on the above spray method, pulsed spray is a variant that applies a pulsing current to melt the filler wire, allowing the welding current to be lower. Thus decreasing the heat input and weld pool area. Giving a much smaller heat affected zone (HAZ) enables use on thinner materials than standard spray transfer and use in all weld positions.

It is also suitable for welding nearly all metals, it is one of the most versatile welding processes. However a special power source with pulse MIG capabilities is required and the process requires the main shielding gas to be argon with a low concentration of CO2.

Equipment.

Equipment required to weld using the MIG process is an appropriate power source supply (referring to the above four methods to know what functions are required), welding gun and wire feed unit, electrode (metal alloy wire), shielding gas supply and a correct earth, regulator and mains supply.

MIG welders are the most common jobs you see around. MIG welding is often described as Arc Welding in many countries, and is considered the most common welding process at present within the welding industry.

MIG welding is one of the easier types of welding for beginners to learn….

TIG Welding

Other name: Gas Tungsten Arc Welding

Abbreviations: TIG or GTAW

Read below or skip straight to the video!

Overview.

The TIG/GTAW welding process uses a tungsten electrode to produce the weld.

The weld area and the electrode are protected by use of an inert shielding gas (Tungsten Inert Gas – TIG), usually argon or helium. A filler metal is usually fed into the weld area – either by hand for manual applications or by use of a wire feed unit in mechanised applications.

However the autogenous and fusion weld methods do not require filler material.

Applications.

Welding together thin stainless steel or non-ferrous metals such as aluminium and copper is the most common use for this method. It allows the operator much greater control over the weld, leading to higher quality and stronger welds.

However this in turn makes the process much more time-consuming than MIG or Stick welding and much more complex.

The TIG welding process is used in industries where the welding of thin wall tube is required, including aerospace and bicycle manufacture.

However it also lends itself well to industries where weld integrity is critical such as the nuclear industry, due to the highly corrosive resistant properties produced, as the weld has the same chemical integrity as the base metal.

Equipment.

Equipment required include a constant current power source (either DC or AC if welding aluminium), welding torch, tungsten electrode, shielding gas and relevant regulator, earth and mains supply. As mentioned filler material can also be added if required.

If you are still confused or unsure on the welding processes available to you or even the type of welding equipment you will need for your project, please feel free to contact us with any questions.

Or use The Welding Institutes (TWI’s) website for more information.

comments

Thanks!

It’s really helpful..

Its short and simple, but thats a good thing, there’s alot of quality especially for beginner welders.

Great tips. It is very informative post. I would definitely try to follow your beginners weldments tips short guide. Thanks for sharing this information with us.

Thank you Nathan. Despite the 13000 miles between our companies, the basics are still exactly the same!! Good luck with the fabrications in NZ

Hey, That’s a nice information.

great information very informative as a DIY welder

Hi Pete

I have taken at look at your web site http://www.plasmacutter.co.nz. Great that you can supply consumables at great prices to clients in New Zealand.

Happy to share your details.

Take care of your beautiful country.

Claire

Thanks for sharing Welding related information.