Live Chat

Have a question? Our staff have many, many years of knowledge and experience and want to share this with you!

Chat NowRecent Posts

- Welding Automation: Boosting Productivity And Eliminating Rework.

- Get New, Resistance Welding Solutions from PEI Here!

- Useful Sub Arc Welding Troubleshooting Tips for Improving Your Results.

- Which TIG Welder? A Comprehensive Buying Guide to Make the Best Choice!

- How Pulse MIG Welding Works: All You Need to Know; Will it Work For You?

Recent Comments

- Westermans on Industry Renowned Weld Cladding Machine for the Best Results

- ferdinand verdadero on Industry Renowned Weld Cladding Machine for the Best Results

- Remy on Can You Easily Run a Welding Machine off a House Electrical Supply?

- Westermans on Which TIG Welder? A Comprehensive Buying Guide to Make the Best Choice!

- Erik's Junk Cars on Which TIG Welder? A Comprehensive Buying Guide to Make the Best Choice!

Archive – Monthly

Archive – Yearly

Categories

- Client Projects and Updates

- Customer Resources

- FAQs

- How To…

- Jobs – welders

- Machine of the Week

- New Stock

- Plasma Cutters

- Testimonials and Customer Comments – Welding Equipment

- Tom and Paul Welding Guides

- Uncategorized

- Videos

- Wanted

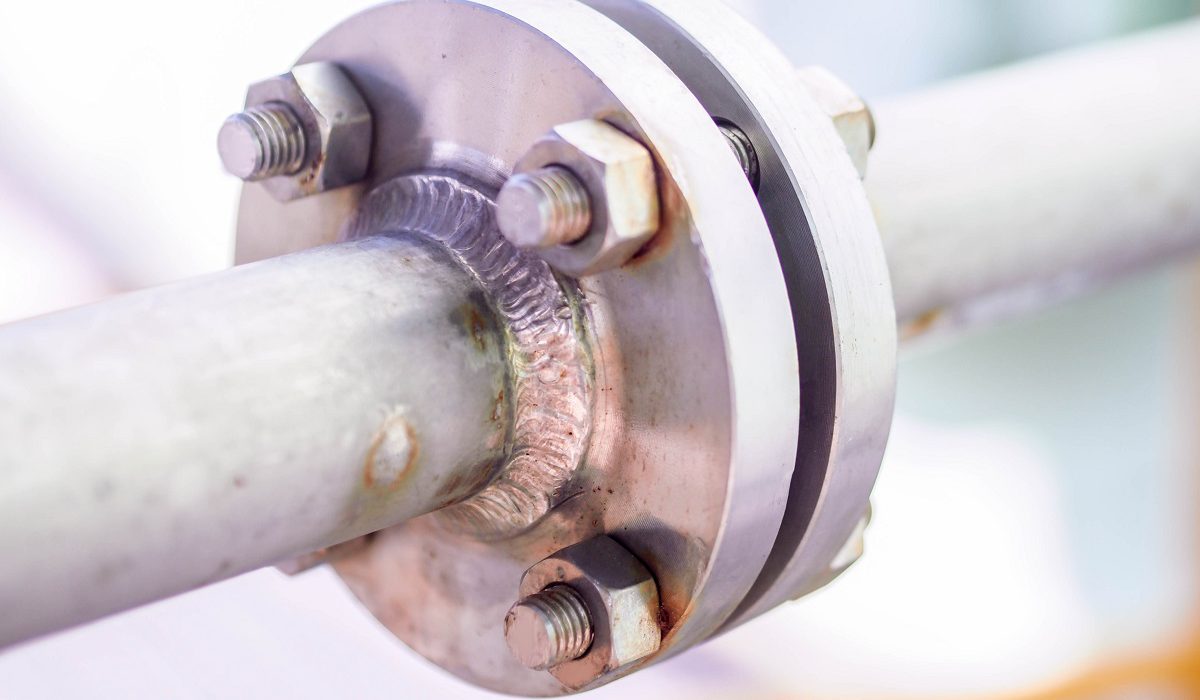

- Welding and Cutting Processes Information

- Welding Showcase Series

- Westermans News

SELL YOUR MACHINE TO WESTERMANS

Westermans buy the widest range of used medium to heavy duty industrial welding and fabrication equipment from around the world.

Sell My Machine »

email

Register Now!

to receive our latest Stock Updates & Exclusive Offers

By submitting your details you consent to their use in accordance with our Privacy Policy