Welding machine maintenance isn’t just a good habit—it’s essential. Whether you’re using new or used welding equipment, the right maintenance routine will extend your machine’s…

Renewable Energy Welding For Wind, Solar, And Hydro Projects

Welding is among the most influential industrial processes affecting renewable energy production. If you use less-than-adequate equipment, project delays and added costs are far more…

Successful Welding In The Oil and Gas Industry

The oil and gas industry was responsible for 54.7% of global energy consumption in 2023, and that number isn’t likely to go down quickly. While…

Welding In The Automotive Industry: Equipment, Processes And Techniques

Automotive welding in production and repair relies on multiple welding processes to meet the regulatory and manufacturer’s standards. Welding technology selection is critical for welding…

Welding Automation: Boost Your Productivity And Eliminate Rework.

The demand for production keeps increasing while fewer people are entering the welding trade than retiring from it. This makes increasing productivity the #1 goal…

Get New, Resistance Welding Solutions from PEI Here!

Westermans Is Taking Over The Agency For PEI Resistance Welding Solutions In The UK And Ireland. If you were a Sureweld customer or are interested…

Useful Sub Arc Welding Troubleshooting Tips for Improving Your Results.

Common problems in sub arc welding can affect weld quality, penetration and overall performance. These sub arc welding troubleshooting tips will identify and address issues…

Which TIG Welder? A Comprehensive Buying Guide to Make the Best Choice!

When it comes to TIG welding, the right equipment can make all the difference in the world. Whether you’re an experienced welder or just starting…

How Pulse MIG Welding Works: All You Need to Know; Will it Work For You?

Pulse MIG welding is a modified spray transfer MIG process that allows exceptional heat input control, better operating characteristics, and higher weld quality than standard…

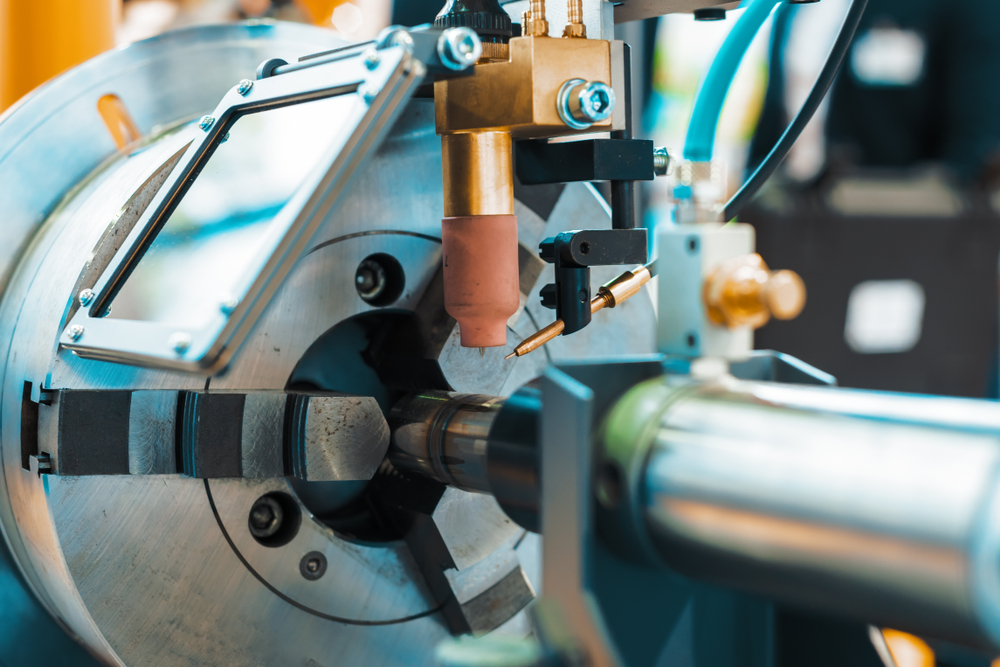

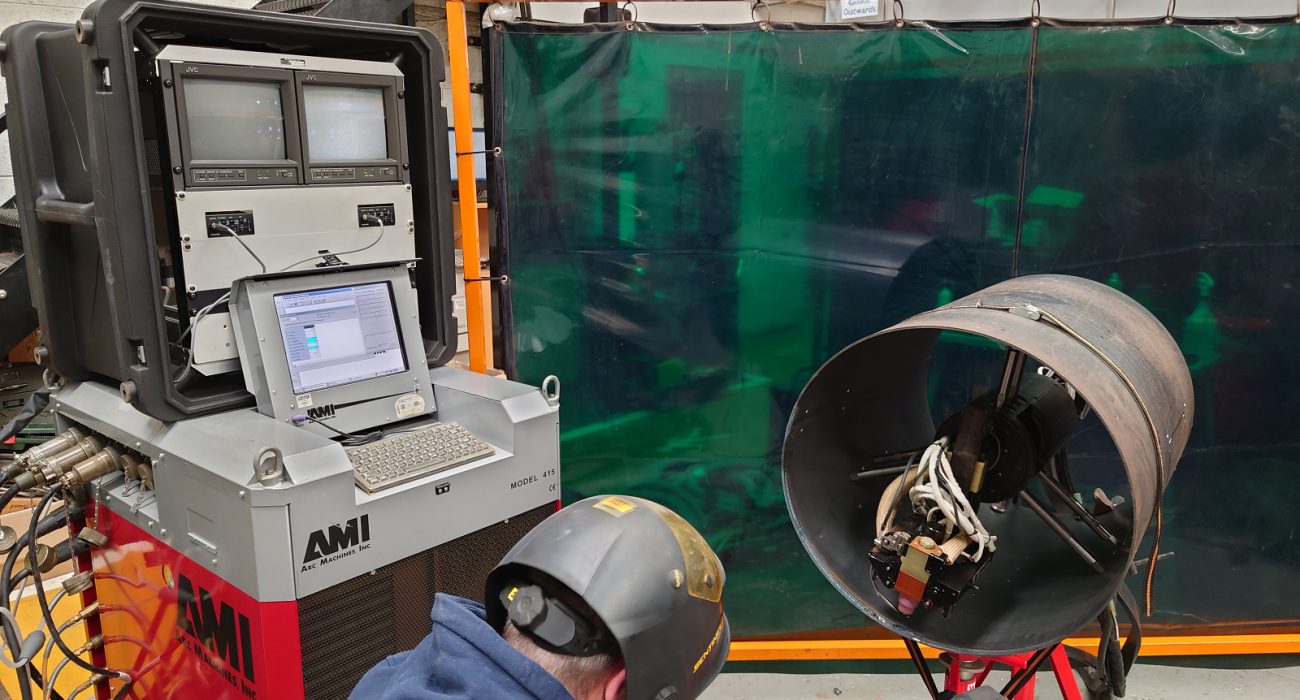

An Insight Into Applications & Industries That Rely on Orbital Welding

No other welding technology can match the quality of orbital for tube and pipe welding. So, let’s dive into orbital welding applications. Learn how it…

The Advantages of TIG Pipe Welding and Applications: Find Out Now

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a highly versatile and efficient welding process. It’s proven to be ideal for pipe…

MIG Welding Aluminium Made Easy: Essential Tips and Tricks!

Aluminium is a versatile and widely used metal in various industries. From automotive and aerospace to construction and manufacturing. When it comes to joining aluminium…

Live Chat

Have a question? Our staff have many, many years of knowledge and experience and want to share this with you!

Chat NowRecent Posts

- 5 Practical Tips to Extend the Life of Your Welding Machine

- Renewable Energy Welding For Wind, Solar, And Hydro Projects

- Successful Welding In The Oil and Gas Industry

- Welding In The Automotive Industry: Equipment, Processes And Techniques

- Welding Automation: Boost Your Productivity And Eliminate Rework.

Recent Comments

- Vivian on Aluminium MIG Welders That Will Change Your Life, Guaranteed!

- Westermans on Longitudinal Welding Made Easy with this Complete Solution from ESAB.

- Gautam Barui on Longitudinal Welding Made Easy with this Complete Solution from ESAB.

- Westermans on Aluminium MIG Welders That Will Change Your Life, Guaranteed!

- Jason Sheil on Aluminium MIG Welders That Will Change Your Life, Guaranteed!

Archive – Monthly

Archive – Yearly

Categories

- Client Projects and Updates

- Customer Resources

- FAQs

- How To…

- Industries

- Jobs – welders

- Machine of the Week

- New Stock

- Plasma Cutters

- Renewable Energy

- Testimonials and Customer Comments – Welding Equipment

- Tom and Paul Welding Guides

- Uncategorized

- Videos

- Wanted

- Welding and Cutting Processes Information

- Welding Showcase Series

- Westermans News

SELL YOUR MACHINE TO WESTERMANS

Westermans buy the widest range of used medium to heavy duty industrial welding and fabrication equipment from around the world.

Sell My Machine »Register Now!

to receive our latest Stock Updates & Exclusive Offers

By submitting your details you consent to their use in accordance with our Privacy Policy