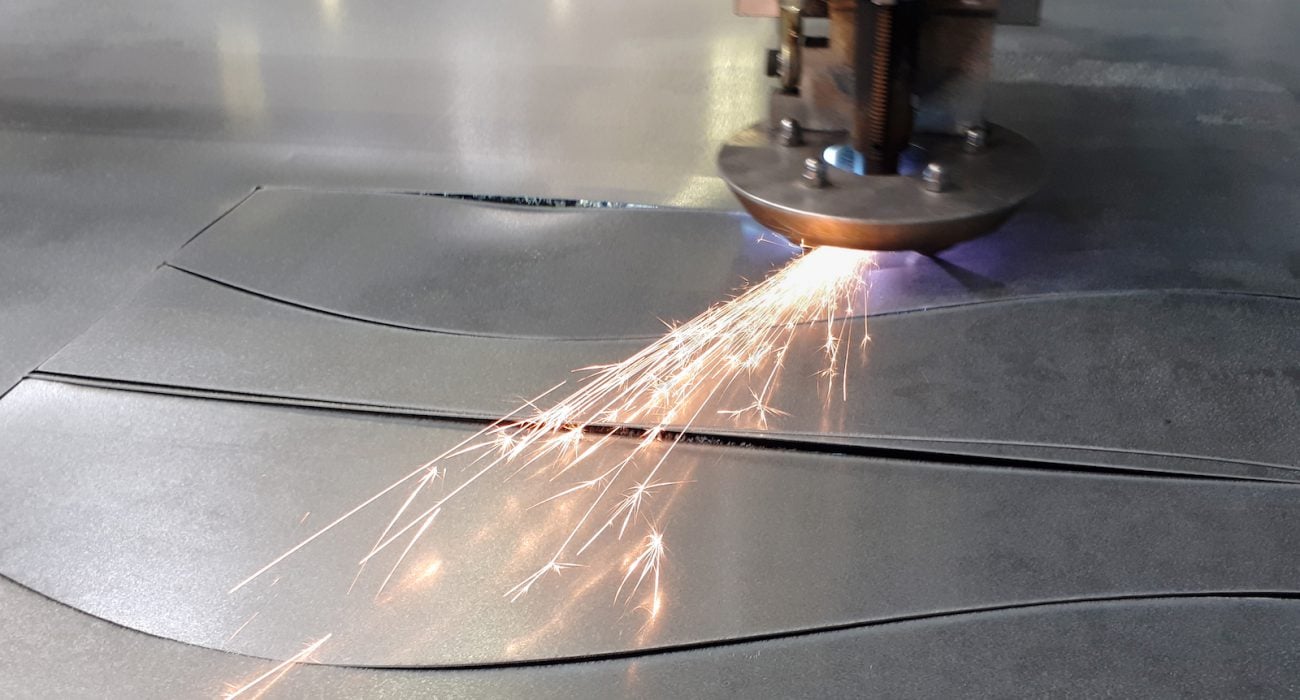

Introduction: What is Plasma Cutting and How Does it Work? Plasma cutting is a process of cutting and shaping conductive materials. It is a key…

The Ultimate Guide to Buying a Welding Fume Extraction System

Introduction: Understanding What is Welding Fume Extraction. Welding Fume Extraction is a process of controlling air pollution from welding fumes. It involves the use of…

How to Use a Stud Welder for Successful Welding Results.

Introduction: What is a Stud Welder and How Does it Work? A stud welder is a welding machine used to join two pieces of metal…

The Beginner’s Guide to Stud Welding: Essential Knowledge You Need

Introduction: What is Stud Welding? Stud welding is a process of joining two metals together using a metal stud as the joining element. This process…

The Best Diesel Welders for On Site Welding.

Introduction: What is a Diesel Welder Generator and What Are the Benefits? A diesel welder generator is a device that combines the power of a…

Everything You Need to Know About Gases for MIG Welding.

Introduction: What is MIG Welding and Why Do We Need Gases? MIG welding is a popular technique used by metal fabricators and welders. It uses…

Machine Tools; What You Need to Know and Their Uses in the Manufacturing Industry

Introduction: What is a Machine Tool and How Does it Work? A machine tool is a device used to shape and cut metal and other…

Seam Welding: Get Strong, Reliable Welds Every Time.

Updated January, 2025 Key Takeaways: Seam welding is a technique for joining metal components. There are two types of seam welding, resistance seam welding and…

A Comprehensive Guide to Spot Welding: How Does it Work and What is It Used For?

Introduction: What is Spot Welding and How Does it Work? Spot welding is a process that uses two electrodes to create an electrical current, which…

Everything You Need to Know About Semi-Automatic Welding and Its Benefits

Introduction: What is Semi-Automatic Welding? Semi-automatic welding is a type of welding that uses a machine to control the arc and the speed of the…

An Expert Guide on How to Tig Weld Aluminium for Beginners

Introduction: What is Tig Welding and What Are Its Benefits? TIG welding, also known as gas tungsten arc welding (GTAW), is a type of welding…

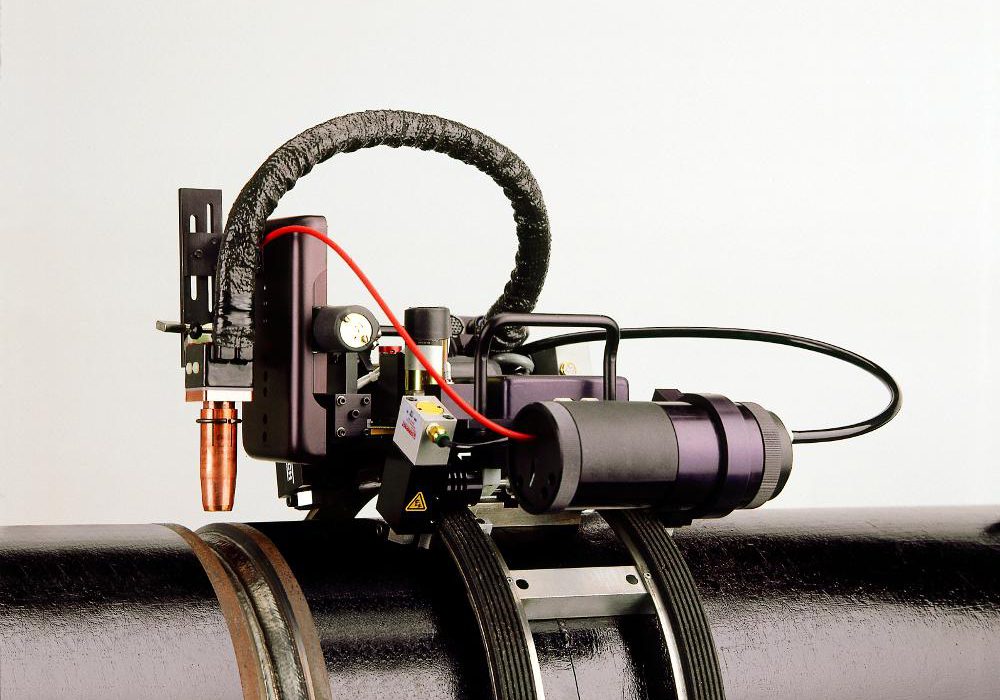

When to Use Pipe Rollers for the Best Welding Results.

Introduction: What are Pipe Rollers and What Are Their Benefits for Welding? Pipe rollers are an essential piece of welding equipment, used to create a…

Live Chat

Have a question? Our staff have many, many years of knowledge and experience and want to share this with you!

Chat NowRecent Posts

- 5 Practical Tips to Extend the Life of Your Welding Machine

- Renewable Energy Welding For Wind, Solar, And Hydro Projects

- Successful Welding In The Oil and Gas Industry

- Welding In The Automotive Industry: Equipment, Processes And Techniques

- Welding Automation: Boost Your Productivity And Eliminate Rework.

Recent Comments

- Vivian on Aluminium MIG Welders That Will Change Your Life, Guaranteed!

- Westermans on Longitudinal Welding Made Easy with this Complete Solution from ESAB.

- Gautam Barui on Longitudinal Welding Made Easy with this Complete Solution from ESAB.

- Westermans on Aluminium MIG Welders That Will Change Your Life, Guaranteed!

- Jason Sheil on Aluminium MIG Welders That Will Change Your Life, Guaranteed!

Archive – Monthly

Archive – Yearly

Categories

- Client Projects and Updates

- Customer Resources

- FAQs

- How To…

- Industries

- Jobs – welders

- Machine of the Week

- New Stock

- Plasma Cutters

- Renewable Energy

- Testimonials and Customer Comments – Welding Equipment

- Tom and Paul Welding Guides

- Uncategorized

- Videos

- Wanted

- Welding and Cutting Processes Information

- Welding Showcase Series

- Westermans News

SELL YOUR MACHINE TO WESTERMANS

Westermans buy the widest range of used medium to heavy duty industrial welding and fabrication equipment from around the world.

Sell My Machine »Register Now!

to receive our latest Stock Updates & Exclusive Offers

By submitting your details you consent to their use in accordance with our Privacy Policy