Introduction: What is Semi-Automatic Welding?

Semi-automatic welding is a type of welding that uses a machine to control the arc and the speed of the weld. This type of welding is used for MIG, TIG, SAW, and plasma arc welding. It’s a popular choice for many welding projects because it offers more precision and accuracy than manual welding. Semi-automatic welding also has the advantage of being faster than manual welding. Thus saving time and money in large projects. Automated arc welding can be used to join different kinds of metals. Such as aluminium, stainless steel, copper alloys, and cast iron.

How Semi-Automatic Welding Can Help with Different Projects.

Semi-automatic welding is a process that uses machines to join two pieces of metal together. It is a great way for welders to save time and money when working on different projects. Many industries use semi-automatic welders, from automotive to aerospace and more. Designed to be fast and accurate, they help welders complete their projects quickly. While still achieving the desired results. There are various types of semi-automatic welding machines available. Each suited for different types of projects and applications. By using one of these machines, welders can ensure that their work is done safely and efficiently.

Advantages of Using Semi-Automatic Welding Compared to Manual Welding.

Semi-automatic welding is a process that offers several advantages over manual welding. These include increased speed and precision. The process involves the use of a semi-automatic welder. Which is capable of performing the same welds as a manual welder but with greater accuracy and speed. This type of welding is ideal for applications that need precision, and fast production times. It also provides more consistent results compared to manual welding. Resulting in fewer defects and improved product quality. Furthermore, semi-automatic welders are easy to operate, requiring minimal training to get started.

What are the Different Types of Semi-Automatic Welders?

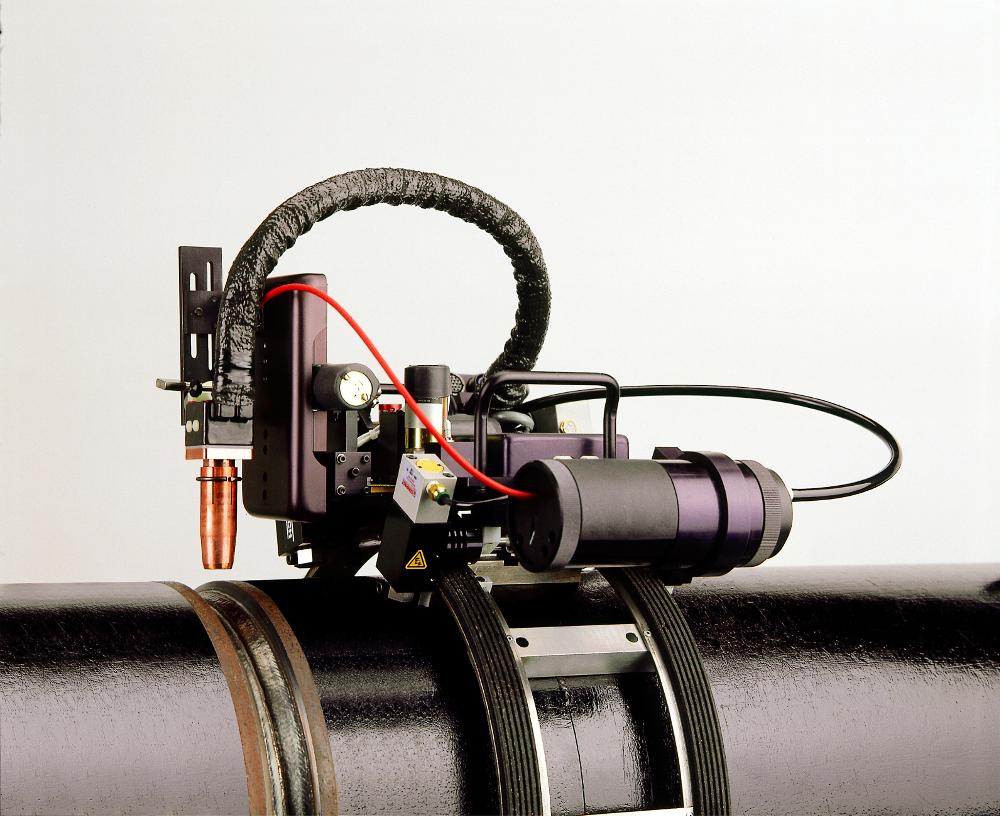

Semi-automatic welding is a process that uses advanced technology to join metal workpieces. It is a cost-effective way to create strong and durable welds with less manual labor. There are three main types of semi-automatic welders. Including the MIG welder, the TIG welder, and flux-cored arc welder. Each type has its own unique advantages and disadvantages. So it’s important to understand which one will be best for your project before making a purchase. Semi-automatic welding solutions include welding carriages, circumferential welding systems and lathes. Plus longitudinal seam welders and column and boom manipulators.

Safety Precautions when Using a Semi Automatic Welder.

When using a semi-automatic welder, safety is of utmost importance. It is essential to take precautions to ensure that the welding process is completed safely. Some of the most important safety precautions include:

- wearing protective gear and PPE

- making sure that all electrical connections are secure

- ensuring that the welding area is clear of any combustible materials.

- installing appropriate fume extraction solutions

- read and understand the user manual for your semi-automatic welder

By taking these precautions, you can help ensure that your welding will be safe and successful.

comments

Pingback: Everything You Need to Know About Semi-Automatic Welding – Mynewcaraccessories.com