Why Upgrade to a Longitudinal Seam Welder?

When seam welding, a continuous weld is created along the weld joint, hence the name “seam” weld. If you manually carry out linear welding, you should consider upgrading to a longitudinal seam welder.

This video shows a bespoke system we supplied to a customer after carrying out some sample welds before they invested in the equipment.

Our Engineers fitted a new ProArc seam welder with a Lincoln Electric submerged arc set up to to meet both spec and budget.

What is Longitudinal Seam Welding?

Longitudinal seam welding is a process used to produce welds along the length of your workpiece on a wide variety of parts. For many industrial applications it is necessary to form the material into a desired shape, e.g. a cylinder or rectangular tube, and then weld the edges to form a rigid structure.

This procedure can be performed for both flat and corner welds. Seam welding is almost always performed whenever pipes and tubes must be joined. Seam welds are more durable and stronger than stitch welds since they cover the entire length of the weld joint.

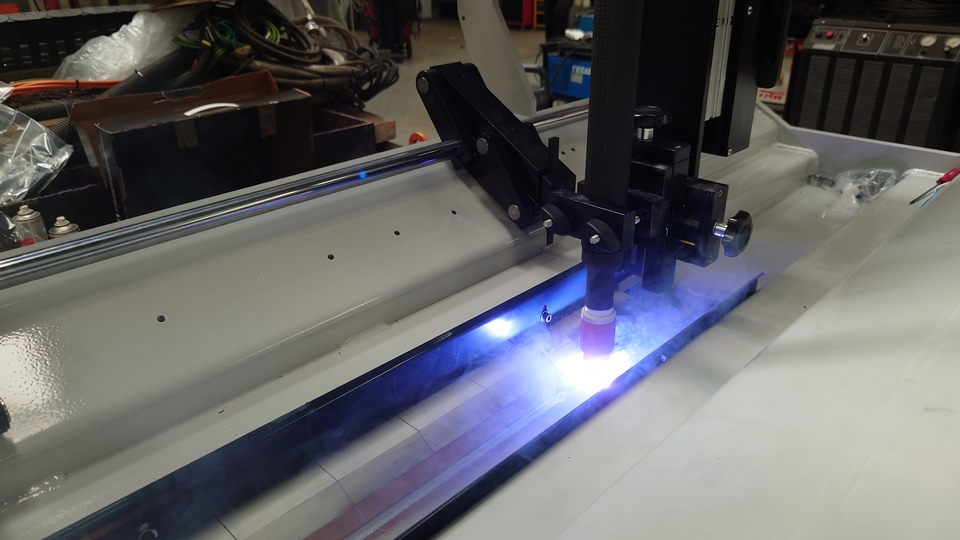

Image showing welding process using a longitudinal seam welder

The Problem with Manual Seam Welding.

The traditional method of doing this is to manually hold the edges in alignment, tack weld them and them complete the linear weld. The weld is done manually, or by use of a simple carriage carrying the welding torch. This type of procedure is costly and time-consuming for the following reasons:

- Holding the edges accurately in alignment is difficult for the full length of the part.

- Tack welding takes time and leads to defects in the are of the tack weld

- There is little effective chilling of the weld joint area leading to distortion and oxidation of the weld and surround area

- Maintaining the dimensional accuracy of the part is difficult

Why a Longitudinal Seam Welder will Optimise Your Welding Process.

Longitudinal seam welders provide a solution to these problems. They optimise the welding process by producing ultra-precise, consistent welds along the length of the seam. Being automatic or semi-automatic increases productivity, as well as reducing costs. This automation also helps to reduce defects, adding to the cost reductions, as well as reducing scrap, increasing weld quality, and reducing energy consumption. They are designed for the straight-line welding of all weldable material in varying thicknesses and workpiece diameters.

New Longitudinal Seam Welder made by ProArc, sold by Westermans

How does a Longitudinal Seam Welder Work?

The longitudinal seam welder clamps the material to be welded firmly in alignment, giving uniform chill to the weld. It also provides the facility to move the welding torch accurately along the weld seam. This produces a butt weld free of melt-through, burn-back and extreme shrinkage or distortion. The user-friendly controls and display make completing the job easy and hassle-free!

Benefits of a Longitudinal Seam Welder.

- They can be used for external or internal welding applications

- Various welding process can be added; MIG/MAG (GMAW), TIG (GTAW), submerged arc (SAW) or plasma welding.

- Simplified controls reduce the operator’s fatigue.

- Options available to adjust mandrel height for varying vessel diameters.

Longitudinal Seam Welder Applications.

External style seam welders are used in the making cryogenic tanks and exhausts. Internal style seam welders are designed for the welding of tanks and vessels and an example of the industry would be the oil and gases by road transportation. Stainless steel manufacturers who are involved in making vessels and tanks for the food and beverage industry would benefit from the semi-automatic seam welding procedure.

Example of stainless steel vessels that can be manufactured using a longitudinal seam welder

Longitudinal Seam Welder Manufacturers.

These semi-automated, longitudinal seam welders are produced by a number of leading manufacturers. We can highly recommend the following:

- Bode the British leaders in positioning machinery

- ProArc offer intuitive, easy to use, new machines maximising value for money

- Jetline are a U.S manufacturer of welding automation products

- Weldlogic are also based in the U.S, manufacturing automated welding solutions for precision applications.

Conclusion.

If you would like to know more about this welding process, the equipment, or are looking for a welding and fabrication firm to our source your longitudinal welding requirements, please get in touch and mention this Blog. We are sure we can help you.

Not sure it is the application for you? Send your material to us and we can carry out some sample welds to ensure before you invest the equipment can do what it says.

Westermans are buyers and sellers of new, second-hand and refurbished Longitudinal seam welders. View here the current list of seamers available today.

All are bespoke and can have various welding processes added or use your existing equipment to save costs – plasma welding, sub-arc or GTAW welding applications.

comments

It’s interesting how you said that a longitudinal welding machine helps to optimize the welding process. This would be really helpful if you were a steel fabrication company that needed to get a lot done. You could just throw everything in the machine and let it do its work.

Hi Wayne if only life was that simple! We also need qualified welders and fitters in our world. This is semi automatic and of course need someone experienced checking the quality of the welds. It does mean welds are consistent if everything else like materials, gases and speeds remain the same. Thanks for your comments – appreciated.

Thanks for sharing this post, it helps me to do the job more efficiently