Live Chat

Have a question? Our staff have many, many years of knowledge and experience and want to share this with you!

Chat NowRecent Posts

- 5 Practical Tips to Extend the Life of Your Welding Machine

- Renewable Energy Welding For Wind, Solar, And Hydro Projects

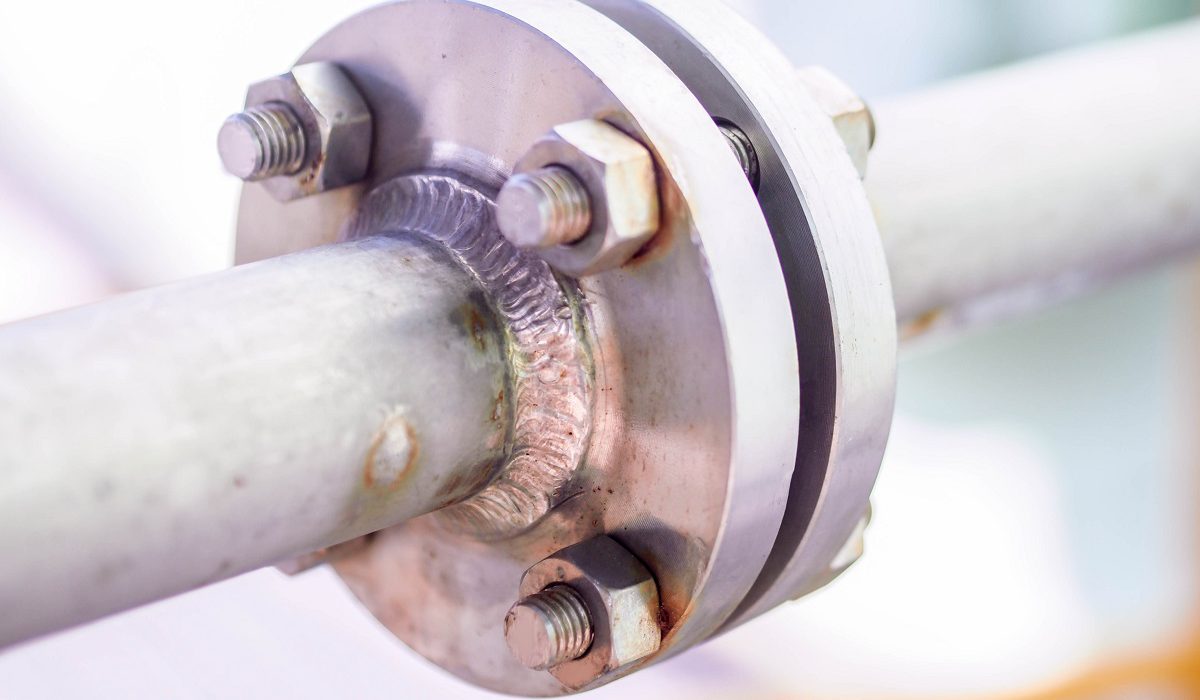

- Successful Welding In The Oil and Gas Industry

- Welding In The Automotive Industry: Equipment, Processes And Techniques

- Welding Automation: Boost Your Productivity And Eliminate Rework.

Recent Comments

- Vivian on Aluminium MIG Welders That Will Change Your Life, Guaranteed!

- Westermans on Longitudinal Welding Made Easy with this Complete Solution from ESAB.

- Gautam Barui on Longitudinal Welding Made Easy with this Complete Solution from ESAB.

- Westermans on Aluminium MIG Welders That Will Change Your Life, Guaranteed!

- Jason Sheil on Aluminium MIG Welders That Will Change Your Life, Guaranteed!

Archive – Monthly

Archive – Yearly

Categories

- Client Projects and Updates

- Customer Resources

- FAQs

- How To…

- Industries

- Jobs – welders

- Machine of the Week

- New Stock

- Plasma Cutters

- Renewable Energy

- Testimonials and Customer Comments – Welding Equipment

- Tom and Paul Welding Guides

- Uncategorized

- Videos

- Wanted

- Welding and Cutting Processes Information

- Welding Showcase Series

- Westermans News

SELL YOUR MACHINE TO WESTERMANS

Westermans buy the widest range of used medium to heavy duty industrial welding and fabrication equipment from around the world.

Sell My Machine »

email

Register Now!

to receive our latest Stock Updates & Exclusive Offers

By submitting your details you consent to their use in accordance with our Privacy Policy