Welding machine maintenance isn’t just a good habit—it’s essential. Whether you’re using new or used welding equipment, the right maintenance routine will extend your machine’s lifespan. As well as reduce costly breakdowns, and improve weld quality.

Key Takeaways – Welding Machine Maintenance

-

Regular maintenance extends the life of welding machines and prevents costly breakdowns.

-

Paying attention to the duty cycle and avoiding overheating protects internal components.

-

Using clean, stable power reduces the risk of voltage-related damage.

-

Keeping machines clean, dry, and properly stored prevents contamination and wear.

-

Operator training is essential for correct machine use and early issue detection.

Contents

- Regular welding machine maintenance schedules

- Duty cycle and overheating

- Power supply requirements

- Condition and storage

- Operator training

Here are five essential tips every workshop should follow:

🔧 1. Stick to a Regular Maintenance Schedule

Routine welding machine maintenance helps catch small issues before they become costly repairs.

-

Clean vents, internal components, and filters regularly

-

Inspect power leads, connectors, and torches for wear

-

Keep a monthly servicing log for consistency. Pro tip: Schedule weekly visual checks and deeper monthly maintenance

-

Get a thorough service of the machine by the manufacturer or professional on a yearly basis

🌡️ 2. Avoid Overheating and Exceeding the Duty Cycle

Overworking your welder is a fast track to early failure.

-

Know your machine’s duty cycle and respect its limits

-

Use cooling fans in hot environments

-

Allow adequate downtime between welding sessions

-

Use a water cooled unit if usage is high and/or the application is heavy duty.

⚡ 3. Use a Clean and Stable Power Supply

Unstable voltage is a common cause of internal damage in welding machines.

-

Install surge protection or a voltage stabiliser

-

Avoid power drops caused by long extension cables

-

Check generator compatibility if working on-site

🧽 4. Keep Your Welder Clean and Covered

Dust, moisture, and metal debris can damage components and reduce machine life.

-

Wipe down surfaces after use

-

Store machines in dry, enclosed areas

-

Use protective covers during downtime or transport

-

Combine with an appropriate fume and dust extraction unit where appropriate to keep air free of contaminants.

🧑🏭 5. Train Operators in Proper Use and Maintenance

Poor handling is one of the most preventable causes of machine failure.

-

Train all users on startup, shut-down, and safety routines

-

Teach signs of early wear, leaks, or irregular sounds

-

Make it standard practice to report performance changes early

✅ Why Good Welding Machine Maintenance Matters

-

Longer equipment life = better ROI

-

Fewer repairs and less downtime

-

More consistent weld quality

-

Higher resale value of used machines

🧰 Need a Well-Maintained Used Welder?

At Westermans, all our machines go through rigorous servicing and testing before they leave the door. Whether you’re upgrading or replacing a faulty unit, we’ve got reliable equipment you can trust.

Or give the team a call to discuss your needs.

Did you know we also offer part exchanges? Say goodbye to the hassle of trying to offload your redundant machine! Speak to one of the team today.

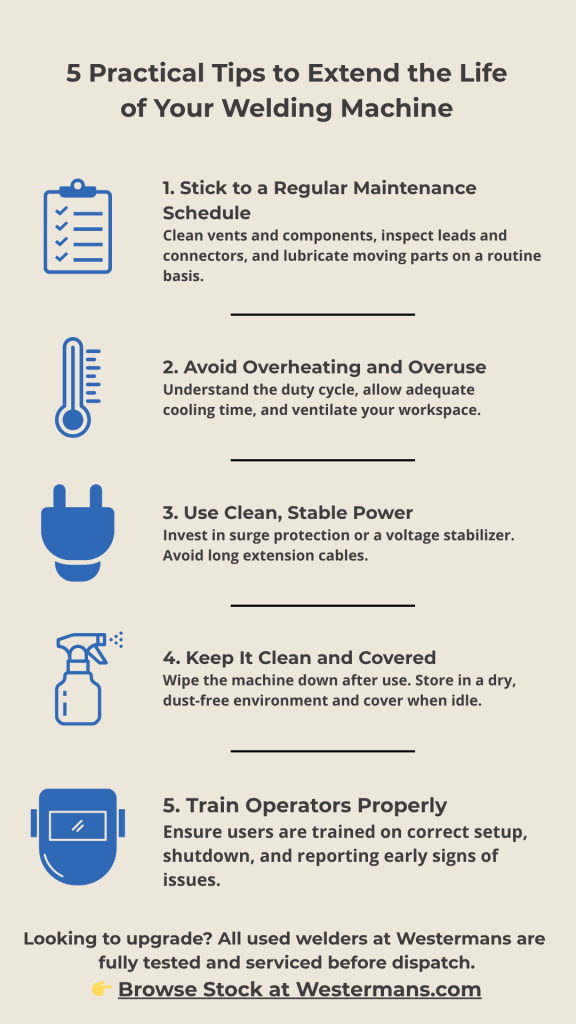

p.s. – view these tips in our handy infographic below!