When investing in welding or fabrication machinery, the decision often comes down to one question – should you buy new or used?

Both options have clear advantages, but the right choice depends on your budget, workload, and long-term business goals. At Westermans, we sell both new and pre-owned welding machines. So we know the pros and cons of each, and we’re here to help you decide what’s best for your workshop.

Key Takeaways: New vs Used Welding Equipment

-

Both options make sense. It depends on your budget, workload, and growth plans.

-

New machines: higher upfront cost, longer lifespan, latest tech, and full warranty.

-

Used machines: lower investment, faster ROI, proven reliability, and sustainability benefits.

-

ROI varies. Used often pays back within months; new may take years but offers long-term durability.

-

No one-size-fits-all answer. The best choice is the one aligned with your current business needs.

-

Westermans advantage. We sell both new and used, so our advice is unbiased and based on what’s right for you.

Contents:

- Why Choose New Welding Equipment?

- Why Choose Used Welding Equipment?

- Quick Q&A: New vs Used Machines

- What to Consider Before You Decide

- The Cost Factor: ROI and Hidden Expenses

- Environmental Impact: New vs Used

- Case Study Snapshot: Saving with Used Equipment

- Why Westermans?

- Final Summary

Why Choose New Welding Equipment?

Buying new has obvious appeal, especially for businesses with heavy-duty needs. Some of the main advantages include:

-

Latest technology. Advanced controls, automation features, and greater energy efficiency.

-

Manufacturer warranty. Peace of mind if something goes wrong.

-

Longer lifespan. A brand-new machine should deliver many years of reliable use.

-

Compliance. If your industry has strict safety or quality standards, new models may help you meet them.

Best for: Businesses scaling rapidly, workshops with high daily output, or operations that need the very latest tech to stay competitive.

Downside? Depreciation curves: New industrial equipment depreciates fastest in the first 2–3 years. Meaning it takes longer to recoup the full cost compared with a lower-priced used unit.

Why Choose Used Welding Equipment?

Used and refurbished machines are a smart choice for many businesses. Particularly those looking to manage costs. While it may seem like a risk to purchase a pre-owned machine, there are many benefits, including:

-

Lower upfront investment. Significant savings compared with new machines.

-

Faster ROI. Shorter payback period, especially valuable for SMEs.

-

Proven performance. Many machines are built to last, and refurbished models can perform like new.

-

Sustainability. Extending the life of equipment supports circular economy goals.

Best for: Small-to-medium workshops and companies, expanding without heavy capital spend. Or businesses testing new capabilities before scaling up. Solutions like welding positioners or rotators, orbital welders for pipe and tube welding, or automation equipment.

Downside? Parts and spares availability can be limited depending on the model. If you’re unsure, just check with the supplier (we often store spares and parts for older models, for this exact reason).

New vs Used Comparison Table

| Factor | New Welding Equipment | Used Welding Equipment |

|---|---|---|

| Purchase Price | Higher upfront investment | 30–50% cheaper than new |

| ROI Speed | 2–3 years typical | 6–12 months typical |

| Warranty & Support | Full manufacturer warranty | Westermans refurbishment guarantee |

| Lifespan | Longer (ideal for daily heavy use) | Varies, but refurbished models can match new performance |

| Resale Value | Depreciates quickly | Holds value more steadily |

| Sustainability | More energy efficient (new tech) | Circular economy benefit (reuse + reduced waste) |

Quick Q&A: New vs Used Welding Equipment

Q: Is used welding equipment reliable?

A: Yes—if purchased from a reputable supplier. At Westermans, every machine is serviced, tested, and quality-checked before sale.

Q: Will a new machine save me money in the long run?

A: Not always. New machines depreciate in value quickly. Used machines often pay back faster thanks to lower upfront costs.

Q: Which option is better for SMEs?

A: Used machines typically deliver faster ROI, but it depends on usage. For daily, heavy-duty welding, new equipment may be more cost-effective over time.

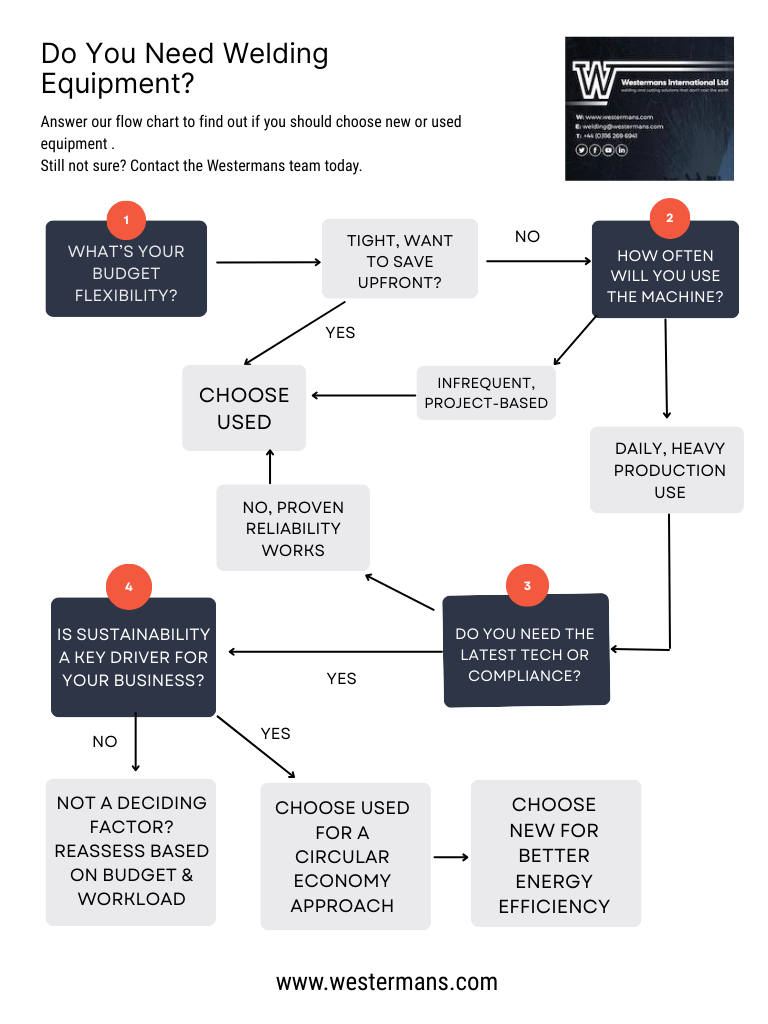

What to Consider Before You Decide

Here are four key factors to weigh when choosing between new and used:

-

Budget and cash flow. Do you want to minimise capital spend, or are you ready for a larger investment?

-

Usage frequency. Will the machine run daily shifts, or just occasionally?

-

Future growth. Will your workload increase in the next 3–5 years?

-

Maintenance & servicing. Can your team handle upkeep, or do you need manufacturer support?

Westermans tip: If you’re looking at introducing a new process or piece of kit, buying a used machine is a cost effective way to trial it out. Upgrade at a later date, and we’ll take your old machine in part exchange!

The Cost Factor: ROI and Hidden Expenses

It’s not just about the purchase price. Consider the total cost of ownership:

-

Servicing and repairs. Both new and used machines need maintenance.

-

Energy efficiency. New models may use less power, lowering running costs.

-

Depreciation. New machines lose value quickly; used machines hold value better.

Craig Westerman, our Sales Director, says:

“Used welding equipment often pays for itself in months. While new equipment can take years to deliver ROI.”

That said, the actual ROI will always vary, depending on:

-

Machine type (automation vs manual kit).

-

Usage intensity (daily production vs occasional jobs).

-

Sector (pipeline, fabrication, shipbuilding, etc).

-

Financing or leasing options.

Find out more about ROI when investing in machinery? Take a look at this in-depth article from T.H.E.M.

Environmental Impact: New vs Used

More buyers are now factoring sustainability into their purchasing decisions.

-

New equipment. Often designed with energy efficiency in mind, reducing long-term carbon footprint.

-

Used equipment. Extends the life of existing machines, reducing waste and supporting the circular economy.

Either option can be an environmentally smart choice, we help you to balance both.

Case Study Snapshot: Saving with Used Equipment

One of our UK clients needed to expand welding capacity but didn’t want to spend six figures on new automation. By purchasing a refurbished system through Westermans, they cut costs by more than 40%! Seeing ROI in under a year.

Want to find out if your business could benefit from welding automation? Read our complete guide.

Craig advises:

“Many SMEs can save 30–50% by choosing used welding equipment over new. Without compromising on performance.”

Why Westermans?

Some suppliers only sell new. Others only sell used. At Westermans, we do both. That means you get unbiased advice and a wide choice:

-

A huge range of trusted brands, new and used.

-

Serviced and refurbished machines, tested by our expert engineers and supplied with comprehensive warranty packages.

-

Guidance to help you make the right investment, not just the most expensive one.

Final Thought

There’s no single right answer to the “new vs used” debate. The best choice depends on your business today, and your plans for tomorrow.

At Westermans, we help businesses of all sizes find the equipment that fits their needs. Whether that’s the latest model or a cost-effective, refurbished machine.

👉 Explore your options today:

p.s. Before investing, directors should also consider the wider commercial implications. Take a look at our deep-dive into questions you should be asking yourself before your next machinery purchase. Avoid costly short-term mistakes and make the best decision for your business, now and in the future.

comments

I’m looking for an orbital welding machine. which has to be suitable SCH10. SS materials Butt joint).

Thanks Kumar for providing the size. We have a wide range of closed weld heads for orbital welding that are suitable for stainless steel pipes.

We have several recommendations – the Axxair with SATFX closed head – it is a new machine and in stock

Learn more in this link https://www.westermans.com/axxair-saxx-201-orbital-tig-power-source-with-satfx-closed-heads.aspx

or we’ve many used AMI orbital closed weld heads we can offer.

Keep an eye out for prices sent to your email address.

I need to buy orbital pipe welding machine used one

Hello Ikeokwu,

You can view all of our orbital welding machines in stock here: https://www.westermans.com/orbitalsystems.aspx

In the meantime I will ask one of the sales team to contact you to discuss your requirements.

Thank you,

Jess