Fronius FPA 9000CC Compact Hot Wire Weld Cladding Station Reduced

This equipment is available for delivery to United States

This equipment is available for delivery to United States

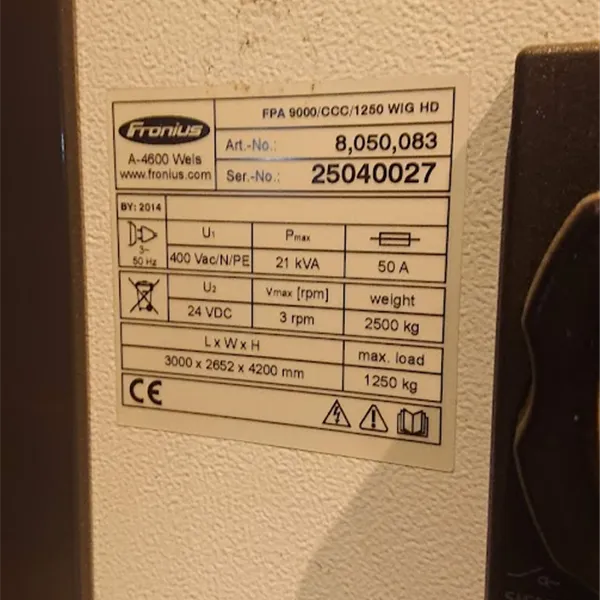

Year of Make: 2011

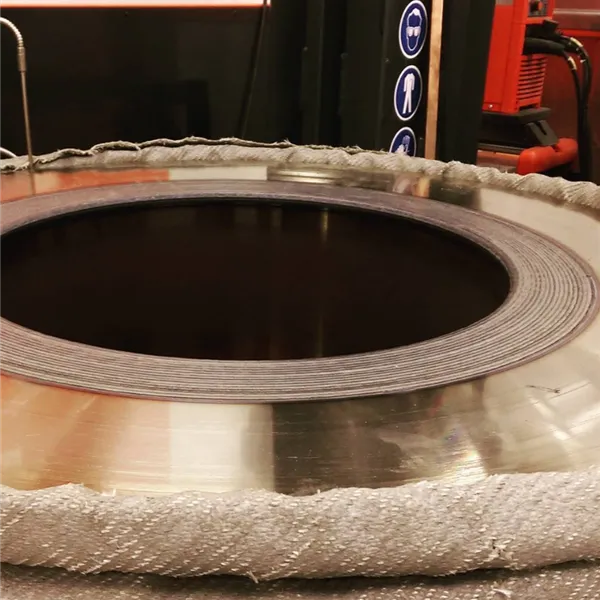

- Fronius Cladding. Weld overlay is a process that provides protection for metallic components by welding a layer of corrosion-resistant alloy to areas at risk of corrosion and wear.

- Benefits of Cladding. Fully cladding a carbon steel component with alloy 625, as opposed to producing it in solid alloy, can reduce costs by as much as 60%.

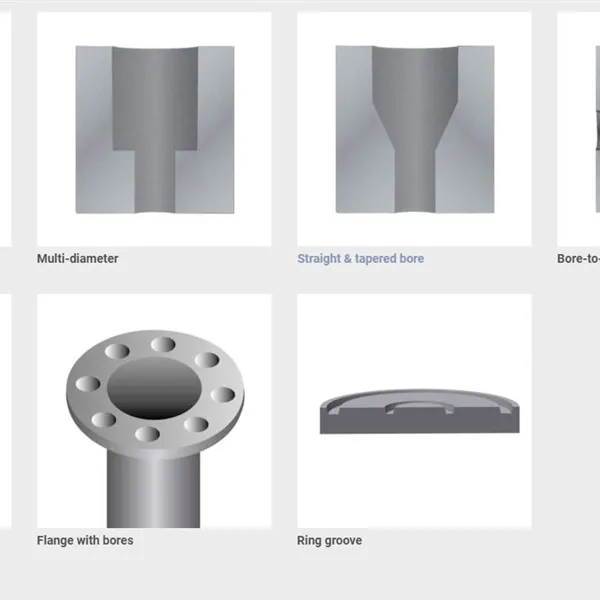

- Applications. Straight bore | cylindrical, bore with bottom face or diameter variation | bore-to-bore, ring groove | straight and conical bore

- The Fronius CC compact cladding cell is designed for maximum cost-effective overlay welding on components up to a diameter of 1m (3.94 in) and a maximum weight of 1250kg

- Perfect for corrosion control in heavy industry, oil and gas industry, food processing and heat exchangers to name a few

- Despite its compact design the Fronius cell is an extremely powerful cladding system that provides simple operation, precise movements and extensive data logging capabilities.

- Compact CNC Weld Overlay Cladding Cell with Fronius FPA 9000 CC Control which has been been regularly calibrated and serviced by Fronius. Last Calibration Date: 29.11.2023 - not used since

- Installed in 2011, removed fully working the package includes

- FPA 9000 CC, TransTig 5000 Job with high-performance cooling unit FK 4000 R and TransTig 2200 Job – fully digital for the best welding quality with TIG hotwire.

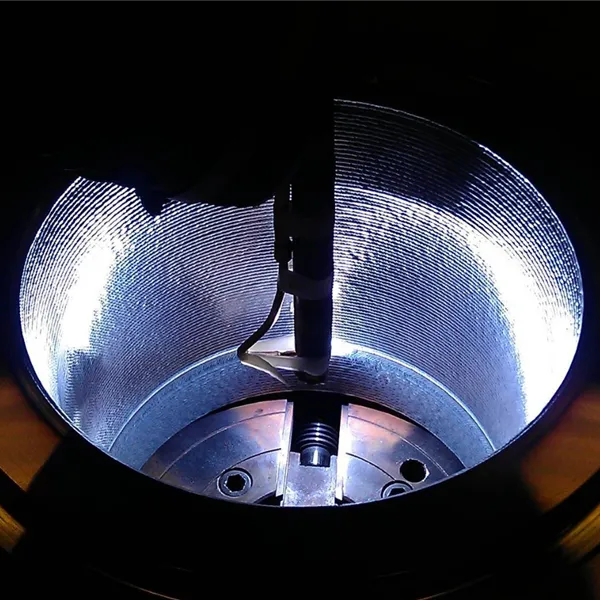

- Column and Boom plus FRT 1000 1000kg Welding positioner fitted with a 1000mm table fitted slip ring systems transfer power when a face plate is rotating and are used to operating heating elements for pre-heating components.

- The TTHW3000M Torch Ø45 allows welding currents up to 300 A. The minimum required inner work piece diameter is 45 mm

- Options: Miller Proheat 35 induction pre heating system (PWHT) available if required with a cable length of 70ft - POA

- Options: Year 2020 Shipping container available for transportation if both Fronius compact systems purchased together. Ask for more details.

Package Includes:

- 4 month warranty

Lead Times

All used machines are serviced/refurbished to order, and lead times are dependant on current workload and machine type. The below can be used as a guide only, and is subject to change. If you have a deadline you need the equipment by, please contact us prior to ordering. We will always do what we can to try and work with your timescales where possible.

- “Sold As Seen” machines: 2-3 working days.

- “Serviced” machines: 7 working days.

- “Refurbished” machines: 2-3 weeks.

- “New” machines: subject to stock and supplier lead times where applicable.

Shipping

All shipping costs include packing.

UK*

- Parcel delivery: from £15 next day courier

- Pallet delivery: from £75

- Large item delivery: TBC by quotation

Northern Ireland

- Pallet delivery: £120

- Parcel and large item delivery: TBC on quotation

Ireland

- Pallet delivery: £220

- Parcel and large item delivery: TBC by quotation

Europe and Overseas

All welding equipment and machinery is sold and supplied Ex-Works, unless otherwise stated. We can however provide full freight forwarding facilities via road, sea or air freight. We work with our reliable shipping partners for one off items, up to the loading of 40ft containers. For a quotation, please contact us with your destination address/port, along with any other specific documentation requirements.

* Rates for mainland UK, subject to change. If in doubt, please send us your delivery postcode for confirmation