The sector of automated and robotic welding and accessories was worth $1.9 billion in 2017.

Welding is used as a fabrication process in every industry, large or small.

It’s a principal means of fabricating and repairing metal products.

The process is an efficient, economical, and dependable means of joining metals, however, the manual welding process has its downsides.

Welding by hand requires man power, and with that the room for human error. Plus, there is no capability for repeatability or high volume.

Automated Welding Equipment.

Enter automated welding equipment.

Used and refurbished robotic welding equipment of these popular brands are supplied. Including ABB, Motoman, Fanuc, Cloos, OTC, Kuka, Panasonic, Miller and Lincoln.

We can also fit any welding application – MIG, TIG, plasma cutting and plasma welding onto the welding robot.

The welding equipment market is very mature. However, with the growing trend toward welding automation and the increase in demand from end-user industries, higher growth is expected.

Automated Welding Applications.

Ideal applications for welding automation include:

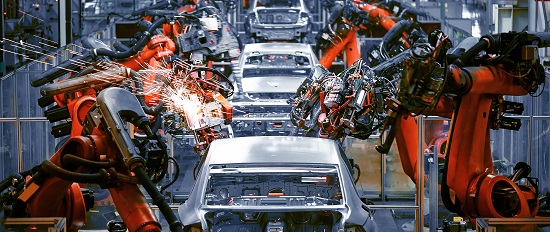

- automobile industry

- construction of buildings

- bridge construction

- ship building

- submarines fabrication

- pressure vessels

- offshore structures

- storage tanks

- oil, gas and water pipelines

- girders

- press frames

- water turbines

The remarkable success of welding-intensive, end-user sectors has galvanized the welding equipment and consumables market. Including the ship building and automotive industries.

An increasing number of industries are automating their production to a large extent. With robotic welding becoming a standard feature of such automation.

The market for welding robots is growing at a higher rate than any other type of industrial robot.

Robotic Welding Equipment.

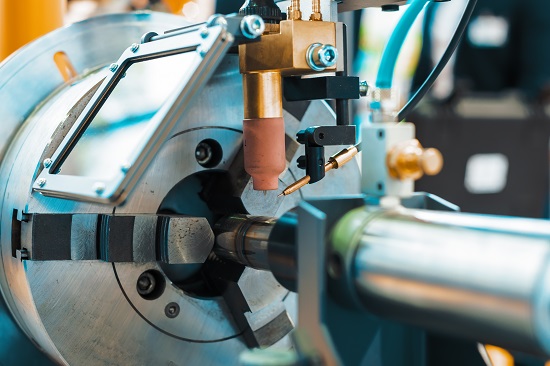

There are two popular types of industrial welding robots; articulating robots and rectilinear robots. Robotics control the movement of a rotating wrist in space.

A description of some of these welding robots are described below:

Rectilinear Robots.

Rectilinear robots move in line in any of three axes (X, Y, Z).

In addition to linear movement of the robot along axes, there is a wrist attached to the robot to allow rotational movement. This creates a robotic working zone that is box shaped.

Articulating Robots.

Articulating robots employ arms and rotating joints, moving like a human arm with a rotating wrist at the end.

This creates an irregularly shaped robotic working zone.

Welding Automation Process Considerations.

There are many factors that need to be considered when setting up a robotic welding facility.

Robotic welding needs to be engineered differently than manual welding.

Some of the consideration for a robotic welding facility are listed below:

Accuracy and Repeatability:

- Number of axes

- Reliability

- Fixtures

- Programming

- Seam Tracking systems

- Maintenance

- Controls

- Weld monitors

- Arc welding equipment

- Positioners

- Part Transfer

A robotic welding system may perform more repeatably than a manual welder because of the monotony of the task. However, robots may necessitate regular recalibration or reprogramming.

Robots should have the number of axes necessary to permit the proper range of motion.

The robot arm should also be able to approach the work from multiple angles.

Benefits of Robotic Welding.

Robotic welding systems are able to operate continuously, provided appropriate maintenance procedures are adhered to.

Continuous production line interruptions can be minimized with proper robotic system design.

Planning for the following contingencies needs to be completed:

- Rapid substitution of the inoperable robots.

- Installing backup robots in the production line

- Redistributing the welding of broken robots to functioning robots close by

How Important is Welding Automation?

Robotic spot and MIG welding are important applications for welding automation, representing about 60% of the world’s robot population.

As the production of robots has increased over the years, the unit cost has decreased. This has allowed companies in the general industry sector (as opposed to automotive), to consider robotic welding. Particularly for medium to high production needs.

Robots reduce labour costs, however, it is a misconception that robots fully replace jobs.

Where is Robotic Welding Implemented?

Typical assemblies in the automotive industry, suitable for robot based welding automation are:

- exhaust systems

- seat manufacture

- cross members

- steering hanger brackets

- engine mountings

- tow bars

- suspension parts.

In general industry, the manufacture of:

- furniture

- gates

- stoves

- bridge sections

- wind turbines.

Items for the yellow goods industry (earth moving vehicles) include:

- buckets

- cabs

- loader arms

- back hoes

In fact, anything that is produced in reasonable volumes can be made by robots.

How Has Technology Changed?

Although the principle of robotic welding has not changed since its introduction in the seventies, suppliers are constantly developing new features.

Thus making it easier to implement with improved performance and lower investment levels.

Benefits of Robotic Welding.

Increased Productivity.

A robot typically works between two or more work stations.

This means that during the robot welding cycle, the operator is unloading a welded assembly, then loads new components to a welding fixture.

Because there is less handling compared to a manual weld cycle, the robot achieves much higher levels of arc-on time.

The robot also moves very quickly between the joints, yielding a further saving in cycle time.

To assess productivity improvements, it would be appropriate to compare manual welding times with automated welding times.

Time and Cost Savings.

Typically a robot system will increase output by a factor of two to four, depending on the nature of welding.

An assembly with lots of short welds can be produced with the most time savings.

The cost savings that robot welding brings can help companies to be more competitive. Allowing them to beat off competition from low cost manufacturing countries in Eastern Europe or China.

Weld Quality.

The robot has a very high repeatable accuracy (± 0.08 mm) and excellent path following accuracy.

It presents the welding gun at the correct welding angle, welding speed and distance. A high level of integration to the welding equipment ensures optimum welding conditions. These can then be used for each and every joint.

The end result is consistent, high quality output, day in day out, year in year. With reduced cost for rework, scrap or removal of weld splatter.

Consumable costs.

It is up to the judgment of a manual welder to weld to the correct standard, but often the weld is oversize.

A robot however, always welds to the correct length and size of weld that it has been programmed to produce. This means that some potential savings in wire consumption can be made.

If, for example, a manual welder welds a 5 mm fillet where only a 4 mm fillet is required, the savings in welding wire alone will be a staggering 36%!

Labour.

In recent years, it has become increasingly difficult to employ manual welders.

There tends to be a certain amount of staff turnover, carrying a cost for recruitment and training.

When labour is an issue, companies often find themselves working overtime or having to employ additional contract labour. Meeting these demands can have a serious impact on production costs.

If products cannot be supplied to the end customer, penalties may be incurred or future business may be at risk.

Whilst there will always be a requirement for manual welding, companies that invest in robotic automation are much less dependent.

Welding Automation Safety.

A robot welding system addresses health and safety issues associated with dangerous welding fumes and exposure to arc-flash.

Improve working conditions and avoid costly sick leave, while reducing the risk of employees claiming compensation. This is particularly applicable to welding in a hazardous working environment.

Flexibility.

The robot can be used to weld many different products and allows companies to consider Just In Time production.

By reducing work in progress and stock levels, savings can be made due to fact that less value is added to stock levels. Including terms of labour, transport and storage costs.

Floor space.

Compared to the same output from manual welding bays, the robot requires less floor space.

They can carry out work in areas that would be unsafe for humans, and not economically viable in a high wage economy.

Robots Designed for Arc Welding.

In 2003, the world saw the launch of a Motoman robot specifically designed for arc welding.

The upper arm of this robot consisted of two sections, through which the welding hose bundle is guided. This arrangement offers higher protection to wear and tear compared to the traditional dressing method, where the hose bundle runs over the top of the upper arm.

In addition, it facilitates robot programming, since the programmer does not need to consider the hose bundle which could otherwise get snagged up in the assembly or fixture.

A better guided, shorter hose bundle offers consistency and improved quality when welding conditions are critical.

Robot controller.

Inside the cabinet is a power supply, a computer, servo amplifiers and communication boards. These can be simple I/O boards, or field bus boards.

Sometimes, an analogue interface card is required to control the speed of the wire feeder of the welding equipment. However, this can also be done via a field bus board, ethernet, or even the serial connection of the computer.

As part of the robot system is also a teach pendant.

Working envelope.

The working envelope of a robot is shaped like a fist, and, when floor mounted, the maximum reach is usually in line with the motor for the lower arm joint. For this reason, the robot may be placed on a base frame.

The envelope of the robot will extend in a circular motion, and the work piece will be placed inside the working envelope.

You can also see that the area at the top is wider and for good reason. It’s sometimes necessary to invert the robot, if it has to weld an assembly that is wider than the envelope. Or if a larger robot cannot be used either.

Robot axes.

The articulated arm of the robot has 6 degrees of freedom or axes, which are driven by electric, brushless AC motors from the robot controller.

Most robot manufacturers refer to these axes as 1 to 3 for the major axes, and 4 to 6 as the minor axes. They are also referred to by their logical names; “swing”, “lower”,”upper”, and then “upper”, “rotate” and “bend”.

On the teach pendant, you will find six clearly marked toggle keys, making it easy to find your way round if you are new to robot programming.

Robot speed.

Robot manufacturers will specify the relevant speeds for each of their robot axes.

In an arc welding robot program, there are often very small moves between welds not allowing the robot to reach maximum speed.

The most important factor is for the robot to accelerate as fast as possible, reach its maximum speed, and then decelerate to the next welding position. This must be done as quickly as possible.

Generally, the speed of the robot is restricted to its slowest axis, as it is a good idea to select “joint moves” for air moves between welds. In this mode, the robot will move to its programmed position in the fastest possible way, irrespective of path.

Robotic Software.

This kind of control is taken care of within the dynamic model, which is part of the the motion control software. The software also considers the weight of the tool at the end of the robot arm, and additional loading. This includes the wire feeder, friction in the joints, and any other external forces that act upon the robot such as gravity.

This dynamic model also ensures that all the motors work in harmony with each other, resulting in good path following accuracy and very high positional accuracy.

Robotic Arm Reach.

The industry standard is a machine with about 1.4 m reach from the centre of the base to the point P. This is the centre of the knuckle joint near the wrist.

It is, however, very useful to have the option of a robot that has a larger reach.

The choice of robot depends on the assembly that needs to be welded.

The Motoman MH50-20 in the tower welding system above is an example of a robot with an extremely long reach.

It is unusual to use such a machine, but in this case is it more economical to use this robot, rather than a standard or inverted robot.

An inverted robot will use the top area of the robot’s working envelope. This is useful if an assembly is otherwise too wide or deep to reach the joints with a floor mounted robot.

Robotic Drives.

Almost all modern robots feature AC servo motors rather than DC motors. Having the advantage that the control system will remember the relevant position of the robot, even after a power cut.

These motors are capable of driving the robot very quickly and accurately, and stop where required without undesirable vibration or backlash.

The servo motors are controlled from servo drive units inside the controller, controlling the speed in relation to the distance from the desired point. This requires the use of tachometers to monitor the velocity and encoders to monitor the the position.

Welding Software.

The computer inside the robot controller not only runs the motion control software, but also the welding software. This provides the robot with a flexible interface to the welding power source.

In order to achieve high quality welding, it is important that the robot can accommodate different welding conditions.

Without this software, it would, for instance, be very easy to burn through thin materials, or have a cold weld on heavy welding applications on starting. Hence the software can mimic the skills of a manual welder and is extremely comprehensive.

Robotic Welding Parameters.

Once the welding parameters have been fine tuned, they are stored and called up for that particular joint condition inside the robot program.

Generally, the parameters are stored as data that divide the weld into three sections; start data, main data and end data.

The number of parameters that can be selected are extensive, and include the following:

- Gas pre-flow and post flow

- Start & end voltage with time

- Main seam voltage or trim if in synergic mode

- Main seam wire feed speed

- Start & end wire feed speed

- Weaving patterns

- Re-start function

- Pulse patterns trim

- Crater fill

- Burn back control

- Automatic re-strike

Machine Interface.

It is also possible to rely on the comprehensive welding software that is resident in the power source. With most customers preferring this kind of interface, since it makes robot programming simpler.

In addition, it is less likely that the operator will corrupt any welding programs.

One of the advantages of this kind of interface is that it is easier to identify any faults, since the responsibilities are clearly identified. This is due to the robot being responsible for moving the torch and the power source being responsible for the process.

How Does the Interface Work?

At the start of the joint, the robotic controller sends a digital output to the power source to select a particular weld schedule.

The robot controller then initiates a signal for the power source to switch on the welding process via the welding interface board.

The power source returns a signal to the robot controller that an arc has been established.

The controller then initiates the movement of the robot.

At the end of the joint, the robot sends a signal to the power source to stop the process and extinguish the arc. The robot moves to the next position in its program, etc.

Handling Equipment for Welding Automation.

When a joint cannot be addressed in the correct welding position, it will be necessary to rotate the assembly. This ensures the robot can weld the joint in the horizontal-vertical position, vertical down hand position, (for materials up to 3 mm thick) or gravity position.

Overhead welding is perfectly OK for a manual process, but should be avoided with a robot. Weld spatter can get lodged onto the tip, resulting in the system stopping due to a weld error.

Welding Positioners for Robotic Applications.

·Positioners, sometimes called manipulators, need to be servo controlled. Driven from the robot controller, they’re programmed from the robot teach pendant.

The movement of the positioner is integrated with the robot, which means that the robot can move to the joint, whilst the positioner is bringing the joint in position.

Alternatively, if the assembly has an orbital weld, the positioner can rotate the assembly, whilst the robot remains stationary or moves along with the joint. Applicable if the orbital weld is eccentric, for example, an exhaust system.

Positioner Handling Capacity.

Welding positioners are specified to a certain handling capacity, depending on the weight of the assembly PLUS the fixture.

The Motoman range of positioners tend to be modular in construction, with handling capacities from 250 kg to a massive 20,000 kg.

Other manufacturers may also have a standard range of positioners, or may be able to manufacture bespoke units.

Types of Robotic Welding Positioners.

There are many types of positioners designed to suit the exact requirements of the assembly that needs to be welded. These can be a single axis or twin axes, single station or twin station.

Below are some examples of the most common types.

Twin-Station Positioners.

A twin station positioner has a positioner on each end of an indexing mechanism. Enabling the robot to weld an assembly, whilst the operator is tending the fixture.

The indexing mechanism is usually servo-controlled, and can either be vertical or horizontal.

A vertical index is like a haymaker wheel, having the advantage of the index movement requiring less space. This makes it the best choice for longer assemblies.

A limiting factor for twin station positioners, is the width of the assembly or fixture.

This should fall within the specified swing diameter, or else there will be interference with the central beam or floor.

Single-axis Positioner.

Also known as a head and tail stock positioners.

The distance between fixture discs may vary dependant on the length of the assembly.

One end is driven by an electric servo motor, whilst the other end is a freely rotating tail stock.

Between the fixture discs will be a frame work, known as a strong back, that will support the fixture.

It is common to have two of these positioners in a robot cell, in order to obtain the benefits of the multi-station approach.

Twin-station, Single-axis Positioners.

The principle is the same as for two single axis positioners, except that the two units are mounted on a station index mechanism. This means that all unloading and loading operations can be done from a single area.

This is often an advantage to save floor space, while saving the operator from having to walk round the system.

The station index can be horizontal or vertical, with a central screen in the centre preventing the operator getting arc flash.

Single-station, Twin-axes Positioner.

This type of positioner has two degrees of freedom.

The face plate can rotate and tilt, making it possible to locate the joint in a gravity position. This is useful when welding conditions are critical. e.g. the welding of boilers or excavator buckets.

Welding in the gravity position also has the added bonus that the welding process is faster.

Twin-station, Twin-axes Positioners.

Two twin axes positioners are mounted from a station index mechanism.

This type of unit can have tail stocks, depending on the type of assembly that is held.

The advantages of the twin station approach are the same as for the single-axis, twin-station positioner.

Linear Tracks.

If the joints to be welded are outside the working envelope of the robot, mounting it on a linear track will extend the reach of the robot.

Short tracks are two-position pneumatic, whilst longer track are servo controlled.

Linear tracks are also used when two workstations are positioned in an in-line layout.

Gantry Systems.

A gantry system dramatically extends the working envelope of the robot.

The robot is inverted and carried in the Y direction along the work piece, and in the X direction if required. It’s also possible to have a Z direction that moves the robot up and down.

The Y axis of the gantry can be long enough to create two separate workstations, in order to increase the system’s productivity.

The additional axes are fully servo controlled, programmed and controlled from the same robot system.

It is also possible to have additional carriers to have multiple robots.

Robots in the Automotive Industry.

Robots have been keeping things moving in the automotive industry for 30 years. The cost-intensive models of the past have, meanwhile, made way for versatile and reliable high-tech robots.

With the development of each new model, robots have gradually become more profitable.

Today, they pay for themselves faster than ever before, breaking new ground with research and development.

No matter what the task – welding, foundry operations, laser applications or palletizing – these multi-talents improve the entire production chain.

From operation in press shops, to paint shops, and final assembly.

It is no wonder that they are considered indispensable in all areas of the automotive industry.

As a company, we do not buy and sell robotic welders every day of the week. However, we are here to help if you need any information, either buying or selling. Click below to contact us today.

comments

I like how you mentioned that robotic solutions are increasing at a higher rate. My uncle mentioned to me last night that he and his friend are looking for a robotic welding solution for faster production of their business and asked if I have any idea what is the best option to do. Thanks to this informative article and I’ll be sure to tell him that he can consult a trusted robotic welding company as they can answer all their inquiries.

Hi John, I assume you are in the States? If so there are many supply and rental firms. It would also depend if you wanted fully automated robotic system or cobot.

ABB, KUKA, FANUC, YASKAWA spring to mind of great manufacturers.

what is the procedure of making robotic welding cell from mechanical design electrical control design , PLC programming to hardware???

Well Amol as we all know robotic systems can be extremely complex and your question cannot be answered in a blog post.

We are aware of many manufacturers who specialise in robotic welding and you should contact them to carry out your research and get some answers.

Regards for all your efforts that you have put in this. Very interesting info. Can you please help me to find the best Tig welder for auto body fabrication??