How to utilise orbital welding for small diameter tubing or pipes, with AMI equipment .

Orbital Welding of small diameter round tubes (defined as round with an OD of 38mm or less), is used in a variety of industrial applications.

This semi automatic welding process provides a reliable, clean method of fabricating fluid systems for a variety of industrial applications.

For joining of small diameter tubing, orbital TIG welding has become the preferred joining method. Particularly for more critical piping systems where weld quality or product purity is a concern.

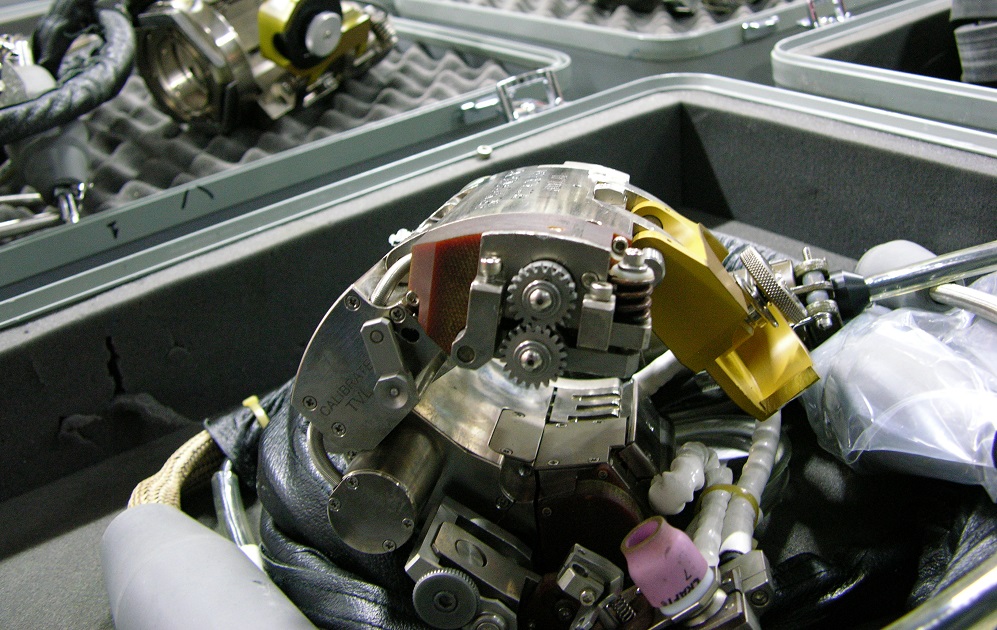

Our Machine of the Week is an AMI Model 81 weld head, which is used in a variety of applications. These commonly include shipbuilding and high-pressure steam piping in fossil fuel power plants.

The Model 81 can be equipped with a wide variety of options to allow its use in specialised applications. These include remote arc viewing vision systems and fillet welding options.

The Arc Machines’ Model 81 is a field-proven weld head, representing years of field experience. It shows in the successful design and development of precision, low-profile, orbital welding heads. The full function, orbital pipe weld head features programmable AVC (arc voltage control), torch oscillation (weaving), onboard Wire Feeder and travel in a very compact package.

Model 81 orbital weld-head in its standard configuration will weld pipe from 1.9″ OD to 5.563″ OD, with as little as 1.750″ radial clearance and 6.325″ axial clearance.

The unique clamping assembly increases production rates by minimizing the mounting and dismounting times of the weld head. This can be to as little as 30 seconds each.

Orbital welding is extremely versatile. It has the ability to fuse together components in a wide variety of sizes and materials.

The consistency of the results are difficult to match using manual welding techniques.

The M81 weld head is compatible with the AMI Model 227 and AMI Model 415 Power Supplies.

Orbital welding has almost always exclusively been carried out by the Tungsten Inert Gas (TIG / GTAW) technique. It uses non-consumable electrodes, with additional cold-wire feed where necessary.

The easy control of heat input makes TIG-welding the ideal welding method for fully orbital welding of tubes.

With the addition of specialist orbital welding heads like this one, it is a versatile process that can be used for a variety of applications.

If you want further details, full specifications and a price on the AMI M81 weld head we have for sale, please complete the form in this link

Or call our Sales Office for this and other recommendations of new and used orbital welding systems for your welding projects.

comments

Pingback: Orbital welding for small diameter tubing from AMI – Site Title