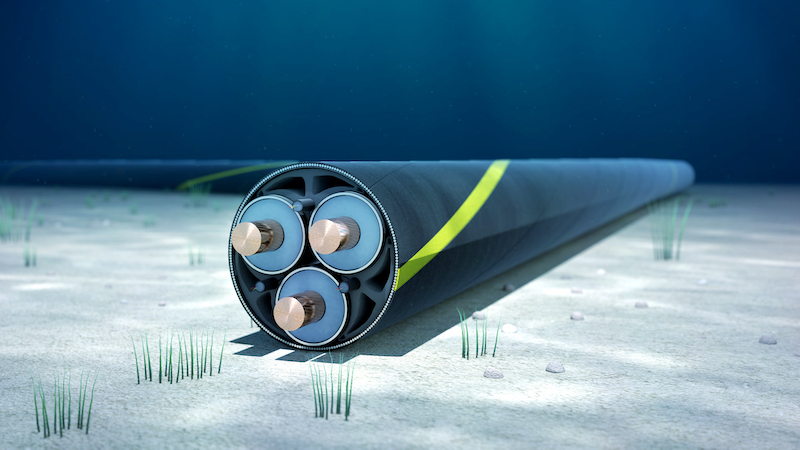

Polysoude hot-wire orbital welding for subsea umbilicals.

Welding equipment manufacturer Polysoude has been chosen by Nexans, a worldwide cable manufacturer using orbital Hot Wire equipment with significant gain in productivity and even reduced delta ferrite content for its subsea products.

Since 2004, Nexans places its confidence in Polysoude for acquiring its orbital welding equipment and the development of related welding procedures. In 2013 the use of the Hot Wire process represents a new step in this highly complex manufacturing process.

Watch this…. A very clever video showing the umbilical cabling manufacturing process.

Impressive!

- Nexans is a manufacturer and supplier of advanced subsea products and services for the oil and gas industry, including :

- Power cables,

- Direct Electrical Heating,

- Multifunctional umbilicals for power and Remotely Operated Vehicles (ROV).

- Nexans offer turn-key solutions from engineering and steel tube welding, manufacturing and installation to qualification testing and hook-up

- Umbilicals carrying energy, telecommunications, fluids and chemicals are essential for controlling subsea systems.

- Nexans has developed new stainless-steel tube, long-length, deep-water power umbilicals that can serve the power needs of pumps and subsea processing equipment (up to 36 kV).

- The manufacturing plant in Halden is competence centre with research and development for high-voltage submarine power cables and umbilicals. The plant has continuously been enlarged and upgraded in order to accommodate developments in the field of paper insulated high-voltage AC and DC cables, high-voltage XLPE insulated cables, composite cables, pipeline heating cables and umbilicals for the offshore industry.

FACTS:

Nexans Norway introduced the first steel tube umbilical in 1993 and the first dynamic steel tube umbilical in 1995.

The company has supplied more than 1,800 km of umbilicals, including a record-breaking length of 144 km to Statoil’s Snøhvit and an installation depth of 2,300 m to Shell’s Nakika.

Nexans has furnished power umbilicals for the King Subsea Pump (BP) and the Tyrihans project in the North Sea (Statoil).

Service umbilicals include Atlantis (BP) and Thunder Horse (BP) fields in the GOM, deepwater Akpo and Usan offshore fields for Total in Nigeria, and the Dolphin Energy gas project in Qatar

Direct links on the businesses promoted here are…

AstroArc Polysoude Orbital TIG welding equipment

Nexans Global experts in cables and cabling